The Custom Torque Hinge Roadmap: 5 Key Milestones from Sketch to Mass Production

Defining a mechanical component solely by its torque rating is a primary cause of project failure in precision equipment development. A simple request for a “2.0 Nm hinge” ignores critical variables such as the static-to-dynamic friction ratio that determines tactile quality , or the material specifications required to withstand environments ranging from -40°C to corrosive salt spray.

To ensure product success, engineering teams must transition from vague requirements to a rigorous, data-driven development framework. This guide outlines a standardized five-milestone roadmap that transforms custom hinge development into a transparent engineering process. We detail the essential steps required to mitigate risk, from utilizing DFM simulations for stress prediction to implementing automotive-grade PPAP controls for mass production consistency

Defining Custom Torque Hinge Specs – Beyond Just Torque

Many failed custom projects stem from vague initial requirements. During the Request for Quotation (RFQ) phase, simply stating “need a 2.0 Nm torque hinge” is insufficient.

To ensure design success on the first attempt, we establish an engineering checklist containing the following critical parameters:

Static vs. Dynamic Friction Ratio

This is the core metric determining the user’s tactile experience (haptics).

- The Issue: If the static torque (breakaway force) is significantly higher than the dynamic torque (running resistance), the user will feel a noticeable “stiction” or “jerkiness” when opening the device.

- The Standard: For high-end medical or electronic devices, we recommend controlling the difference between static and dynamic torque to within 15%. This provides a “silky smooth” operation feel.

Outdoor Environmental Adaptability

The operating environment directly dictates the material and lubricant selection in the Bill of Materials (BOM).

- Temperature Range: If the equipment must operate outdoors at -40°C, standard mineral-oil-based damping grease will freeze. This causes torque spikes or even structural fracture. In this scenario, synthetic fluorinated grease is mandatory.

- Corrosion Class: Refer to the ASTM B117 salt spray test standard. For maritime or outdoor EV charging applications, 316 stainless steel or hardened steel treated with QPQ (Quench-Polish-Quench) must be selected to pass 96+ hours of salt spray testing.

Hinge Cycle Life Expectancy

- Consumer Grade: Flip phones or laptops typically require 20,000 cycles.

- Industrial Grade: Heavy machinery access panels may only need 5,000 cycles, but require higher torque stability.

- Failure Definition: Explicitly define “failure.” The standard criteria is: After completing the rated cycles, the torque decay rate does not exceed 20% of the initial value.

DFM & Simulation for Friction Components

Excellent design is calculated, not discovered through trial and error. Before paying for hard tooling, we perform a comprehensive Design for Manufacturability (DFM) analysis on the friction components. This step is typically provided at no cost but avoids 90% of structural risks.

3D Center of Gravity (CoG) Simulation

Many engineers habitually calculate torque based on the geometric center of the panel. This is risky.

- Case Study: A medical display added a camera module to the top bezel, shifting the CoG upward. Without recalculating, the standard torque formula ($T = L \times W \times f$) failed, causing the screen to drift downward at the 90-degree vertical position.

- Solution: We import your 3D model into simulation software to map the gravity moment curve across the full 0 to 180-degree stroke. This ensures the hinge output torque always covers the gravitational moment.

Finite Element Analysis (FEA) for Stress Prediction

High-torque hinges generate immense reaction forces during rotation.

- The Risk: This stress frequently causes cracking at the mounting root of plastic housings.

- The Solution: Using FEA heat maps, we predict stress concentration points. We advise clients to add ribs or metal backing plates in specific areas to ensure mounting strength matches high-torque applications (e.g., applications exceeding 5.0 Nm).

Prototyping & Adjustable Torque Samples

In the Research and Development (R&D) phase, the total weight and CoG of the device are often not finalized. Opening hard tooling immediately risks weeks of delays if the load changes.

We provide two strategies to manage this uncertainty:

CNC Soft Tooling Samples

- Lead Time: 7-10 days.

- Purpose: Functional samples are created using CNC machining or wire EDM. While the unit cost is higher, this allows engineers to quickly verify assembly fit and check for interference.

Field-Adjustable Prototypes

This is a powerful tool for accelerating the R&D cycle.

- The Pain Point: Engineers are unsure if they need a 2.5 Nm or 3.0 Nm feel.

- The Solution: We provide samples with adjustment screws. Engineers can install the hinge on the real prototype in their lab and tune it to find the optimal operating feel.

- The Result: Once the optimal torque value is confirmed, we convert it to a fixed torque specification for mass production to lower costs and improve consistency.

Validating Hinge Reliability & Durability

Untested samples are just toys. Before entering mass production, a rigorous Design Verification Plan and Report (DVP&R) must be executed. Below are three core tests that industrial-grade positioning hinges must pass:

Life Cycle & Torque Decay Testing

- Test Method: Reference ASTM F1578 (Standard Practice for Contact Closure Cycling of a Notebook Computer Hinge).

- Execution Standard: Perform 20,000 full-stroke cycles at a frequency of 10-15 cycles per minute.

- Pass Criteria: At the end of the test, the torque value must not be lower than 80% of the initial specification. This means if the initial torque is 2.0 Nm, it must remain above 1.6 Nm post-test to prevent screen drift.

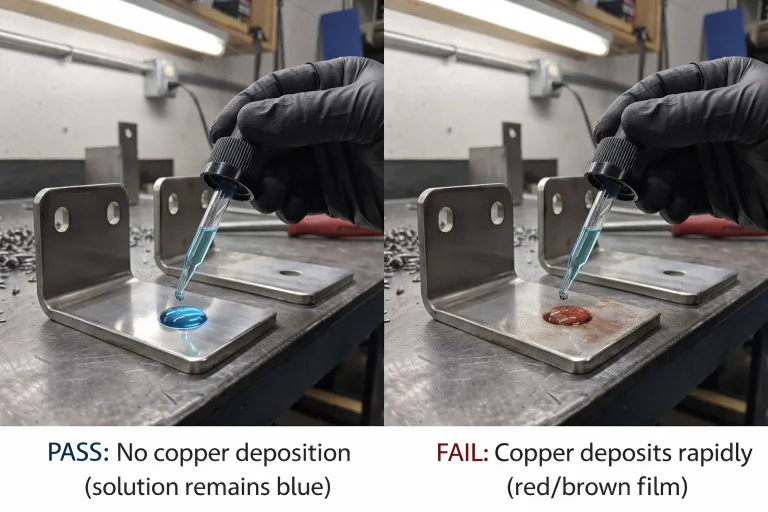

Environmental Resistance Testing

- Salt Spray: Conducted per ASTM B117. For stainless steel parts, we require 96 hours with no red rust; for plated parts, 48 hours with no corrosion.

- Thermal Shock: Conducted per IEC 60068-2-14. Cycling between -40°C and +85°C verifies that the damping grease does not fail or exhibit oil bleed.

Destructive Testing

We test the ultimate breaking strength of the hinge. We typically require a safety factor of 150% or more of the rated torque. This ensures the hinge structure will not suffer catastrophic fracture under user abuse (such as forcing the lid past its stop).

PPAP & Mass Producing Precision Hinges

Making one or two perfect samples is easy; making ten thousand identical units is difficult. This is why we implement the automotive industry’s PPAP (Production Part Approval Process) management flow.

CPK Process Capability Control

The torque of a friction hinge primarily stems from the interference fit between the spring clip and the shaft. Micron-level dimensional deviations can cause drastic torque fluctuations.

- Control Measure: We perform Statistical Process Control (SPC) on the dimensions of critical friction components.

- Goal: Ensure a CPK value > 1.33. This means mass production torque tolerance is stably controlled within ±10%, rather than the industry standard of ±20%.

100% Full Inspection Process

For high-value medical or military orders, random sampling is insufficient.

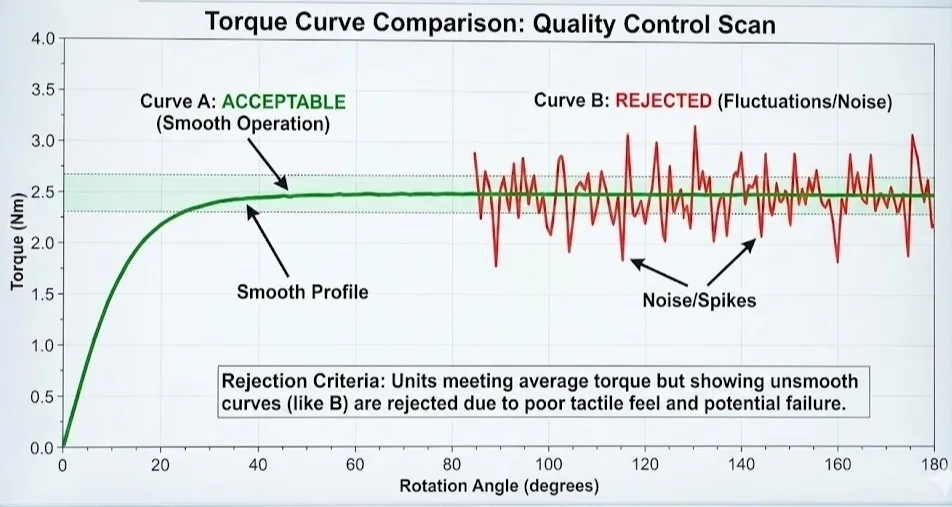

As seen in the chart above, Curve A (Green) represents the ideal ‘silky smooth’ tactile feel we target, while Curve B (Red) shows a unit that technically meets the average torque spec but would be rejected due to ‘noise’ and poor haptics. This is why 100% curve scanning is non-negotiable for high-end applications

- Automated Testing: We use automated torque testers to perform a 100% torque scan on every hinge leaving the factory.

- Data Recording: Every hinge generates a torque curve graph. We reject any units that meet the torque value but exhibit unsmooth curves (fluctuations or noise).

Conclusion: Customization is the Shortcut to Competitive Differentiation

Custom hinges are not a bottomless cost pit; they are a strategic investment in product competitiveness.

Through these 5 standardized milestones, we transform the “black box” of customization into a transparent “white box.” You receive not just a mechanical component that perfectly supports your equipment, but a validated motion control solution compliant with international standards.

Next Steps:

Are you still struggling with hinge selection for non-standard equipment? Do not rely on guesswork to fill in parameters.

Send your 3D drawings (STEP or IGES format) to our engineering team today. We will provide a free DFM manufacturability analysis report and a preliminary torque calculation scheme within 48 hours. Let us eliminate risks at the design stage and ensure your product launches with the perfect operating feel.