Why Do Your Weld-On Hinges Rust? A Complete Guide to Prevention

Weld-on hinges are essential components in outdoor structures such as gates, fences, enclosures, and industrial cabinets. However, constant exposure to harsh environments — including rain, humidity, salt spray, and pollutants — makes them highly prone to corrosion. To ensure long-lasting performance and safety, it’s critical to understand why weld-on hinges rust before learning how to prevent it.

Why Do Weld-On Hinges Rust? — Understanding the Root Causes of Corrosion

[source: Colors and porous surface texture of rust]

Continuous Exposure to Moisture and Oxygen

When metal hinges are exposed to moisture and oxygen for extended periods, electrochemical reactions begin. Iron atoms lose electrons (oxidize) and react with oxygen and water to form iron oxide, commonly known as rust. This process accelerates in environments with persistent humidity or rainfall. [source: Corrosion]

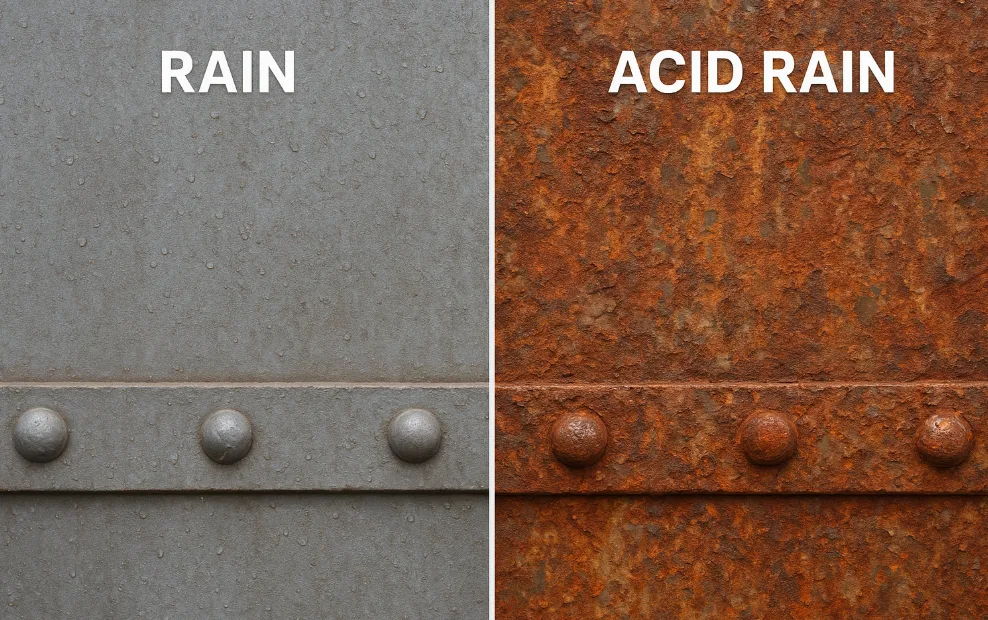

Acid Rain and Industrial Pollutants

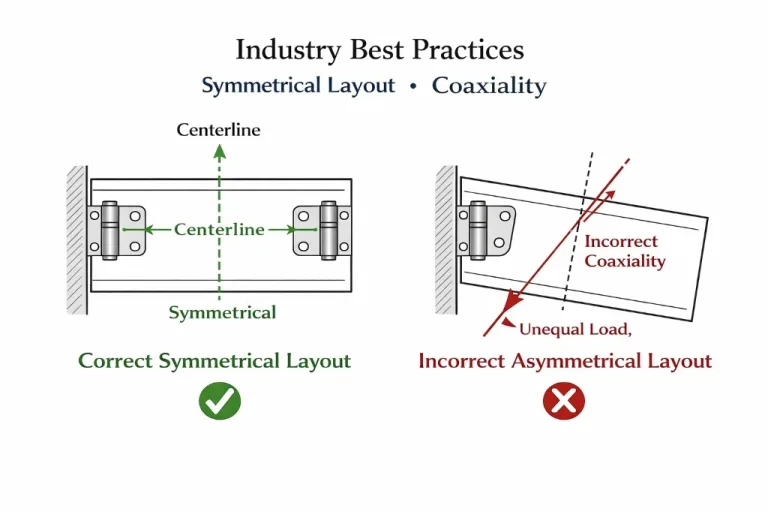

Comparison image of metal surface corrosion caused by acid rain in industrial areas

Rainwater in urban and industrial areas often contains acidic compounds from air pollutants. This mildly acidic water significantly speeds up oxidation, leading to deeper and faster rusting — especially on untreated steel surfaces.

Salt Spray and Coastal Environments

In coastal regions, chloride ions from salt spray penetrate the metal surface, disrupting the protective oxide film and promoting pitting corrosion. Even stainless steel hinges can develop localized rust when exposed to marine air for long periods.

Dust, Grime, and Trapped Moisture

Surface contamination such as dust and grime traps water molecules on metal surfaces, creating micro-environments where corrosion starts. These small moisture pockets become electrochemical cells that cause localized rust spots.[source:Galvanic corrosion]

Temperature Fluctuations and Freeze-Thaw Cycles

Outdoor environments experience frequent temperature shifts. Condensation forms on metal surfaces during cooling, and when freezing occurs, it creates micro-cracks. These cracks expand during thawing, allowing moisture to penetrate deeper and accelerating corrosion.

Welded Areas — The Weak Point of Stainless Steel Hinges

The welding process itself is a critical source of corrosion vulnerability. The high heat alters the metal’s crystal structure and destroys the passivation layer that normally protects stainless steel.

The heat-affected zone (HAZ) around welds becomes chemically depleted of chromium — a key element that provides corrosion resistance — making it the “corrosion hotspot” of the hinge. This localized damage explains why even stainless steel weld-on hinges can rust at seams despite their general corrosion resistance.[ScienceDirect study on weld corrosion]

Selecting Appropriate Rust-Resistant Materials

Stainless Steel

Stainless steel inherently resists rust and corrosion. Specifically, molybdenum-containing 316 stainless steel withstands saltwater and chemical corrosion, making it suitable for coastal or high-humidity environments. Its advantages include strong weather resistance, low maintenance requirements, and a modern appearance. Disadvantages include higher cost and strict heat input control during welding to protect the passivation layer.

Suitable for: Coastal facilities, high-end residential or industrial gates requiring superior rust prevention.

Carbon Steel + Anti-Rust Coating

Carbon steel and cast iron offer high strength and low cost, making them suitable for heavy-duty applications. However, they are inherently prone to rust and require protective coatings. Common methods include hot-dip galvanizing or powder coating to form a barrier layer.

Suitable for: Industrial plant gates, steel fencing, and other applications requiring high strength and cost sensitivity.

Galvanized Steel

Steel is coated with a protective zinc layer via hot-dip galvanizing (hot-dip zinc coating) or electrogalvanizing. Hot-dip galvanizing produces a thick, robust zinc layer that significantly extends service life (typically 20–50+ years),[American Galvanizers Association] though welding requires subsequent coating application. Electrogalvanized coatings are thinner with a smooth finish, offering good initial protection but shorter durability.

Advantages include excellent rust resistance and low long-term costs; disadvantages include limited coating uniformity and welding adaptability. Hot-dip galvanizing is commonly chosen for outdoor gates and fences to achieve extended weather resistance.

Aluminum Alloy

Aluminum alloys readily form stable oxide films that resist rust, offering lightweight surfaces and easy machinability. Advantages include low self-weight and corrosion resistance; disadvantages are low strength, unsuitability for heavy loads, and susceptibility to deformation under large door openings or frequent impact. Aluminum alloy hinges are commonly used in decorative doors or equipment enclosures. To enhance durability, they are often anodized or powder-coated.

Surface Treatment and Protective Coatings

Rust-Proof Primer + Topcoat System

A two- or three-coat system is commonly used to protect steel. First, apply a zinc-rich or epoxy primer to provide sacrificial anode protection and a barrier function. An intermediate epoxy layer may form a dense barrier; finally, a polyurethane topcoat resists UV exposure and mechanical wear. This multi-layer system maximizes isolation from moisture and oxygen ingress, extending protective lifespan.

Powder Coating

Powder coatings adhere electrostatically and cure at high temperatures to form a uniform, highly adhesive film. Properly applied powder coatings can withstand outdoor conditions for approximately 20 years without recoating. Compared to liquid paint, powder coatings are thicker and denser, offering superior scratch and peel resistance while providing long-term isolation from moisture and chemicals. Consequently, powder coating is commonly applied to carbon steel and galvanized hinge surfaces for both decorative and anti-corrosion purposes.

Metal Plating

Common decorative plating includes electroplated chrome and nickel, enhancing gloss and providing initial rust prevention. However, these coatings are extremely thin, offering insufficient wear resistance and long-term rust protection. Electroplating is primarily used in applications with high decorative requirements and light loads, necessitating frequent maintenance to sustain corrosion resistance.

Weld Zone Protection

Welding generates scale and heat-affected rust, as the high-temperature process disrupts the steel’s rust-resistant film. Therefore, oxides should be immediately removed post-welding, welds should be ground smooth, and a rust-inhibiting primer should be applied promptly. After the primer cures, applying a topcoat effectively seals the weld. Where feasible, stainless steel welds can undergo acid pickling and passivation to restore their corrosion-resistant passive film. These measures create a protective barrier near welds, preventing corrosion from spreading.[Nickel Institute guide]

New Coating Technologies

Recent years have seen innovations like self-healing anti-corrosion coatings (containing microcapsule repair agents) and ceramic nano-coatings. Such coatings self-repair upon cracking or damage, or provide ultra-high hardness, significantly enhancing corrosion and wear resistance. Currently, these high-tech coatings are primarily used on high-end equipment in harsh environments but carry higher costs. As the technology matures, it will find broader application in hinge protection in the future.

Anti-Corrosion Details During Installation

Pre-Welding Preparation

Before welding, thoroughly remove oil, rust, and moisture from the joint area. Grind the surface to a smooth finish and ensure it is clean to facilitate full fusion between the weld metal and base material. A contamination-free weld surface minimizes defects and reduces the risk of future corrosion.

Welding Angle and Positioning

When installing weld-on hinges, avoid creating horizontal planes on the hinge leaf where water can pool. Slightly tilt the leaf to facilitate drainage. Simultaneously, avoid welding at low points on door frames prone to water accumulation. Proper configuration design allows rainwater to flow away quickly, reducing prolonged water contact at joints that corrodes metal.

Post-Welding Treatment

Immediately after welding, grind the weld to remove spatter and scale, then thoroughly clean the weld surface. Apply rust-inhibiting primer promptly after cleaning and cure it in an oven. If necessary, seal the weld further by applying sealant or rust-inhibiting oil along the edges. This isolates the weld from air contact, preventing premature corrosion in the welded area.

Drainage and Ventilation Design

To allow hinges to “breathe,” install drainage holes or small gaps at critical points on hinges or door panels during installation to facilitate natural moisture escape. For areas prone to rain exposure, consider adding rain guards or similar protective devices. Most importantly, ensure smooth drainage around the installation site to prevent water accumulation, as prolonged standing water accelerates hinge corrosion.

Post-Installation Maintenance and Rust Removal Techniques

Regular Inspection and Cleaning

Periodically check hinge surfaces for rust spots, cracks, or peeling coatings. Use a neutral cleaner and a soft cloth or brush to remove dust, salt deposits, and other contaminants. For minor rust stains, gently sand the surface with fine-grit sandpaper or a wire brush, then wipe clean with a dry cloth. After cleaning, apply rust inhibitor or rust-proof oil to the hinge surface to maintain a thin protective film on the metal. For areas with peeling coatings or localized paint loss, promptly touch up with rust-proof paint to prevent corrosion from spreading.

Lubrication and Rust-Proof Oil Maintenance

Use specialized lubricating grease on moving parts to maintain lubrication, reduce wear, and prevent rust. Water-resistant, salt-spray-resistant synthetic lubricants are recommended, such as lithium-based grease or PTFE (Teflon)-containing lubricant sprays. These form a durable waterproof barrier on hinge pins and similar components, effectively isolating air and moisture to delay metal oxidation. Wipe off excess grease promptly after lubrication to prevent dust adhesion.

Rust Removal Methods

For surface rust spots, lightly rusted areas can be thoroughly sanded clean with sandpaper or a wire brush. After removing dust, apply primer or rust inhibitor to restore the protective layer. For severe rust causing deep corrosion, use chemical rust removers or rust converters to transform rust into stable compounds before repainting. Always apply a rust-proof coating after treatment.

Preventing Rust Regrowth

Maintain dry conditions for repaired hinges, avoiding prolonged immersion or moisture exposure. After seasonal transitions or wet weather, promptly wipe hinges dry with a cloth and inspect for new rust spots. Regular touch-ups are crucial for preserving the protective coating—conduct comprehensive inspections and necessary repainting every 1–2 years on exposed surfaces. Preventative measures always outweigh remedial actions.

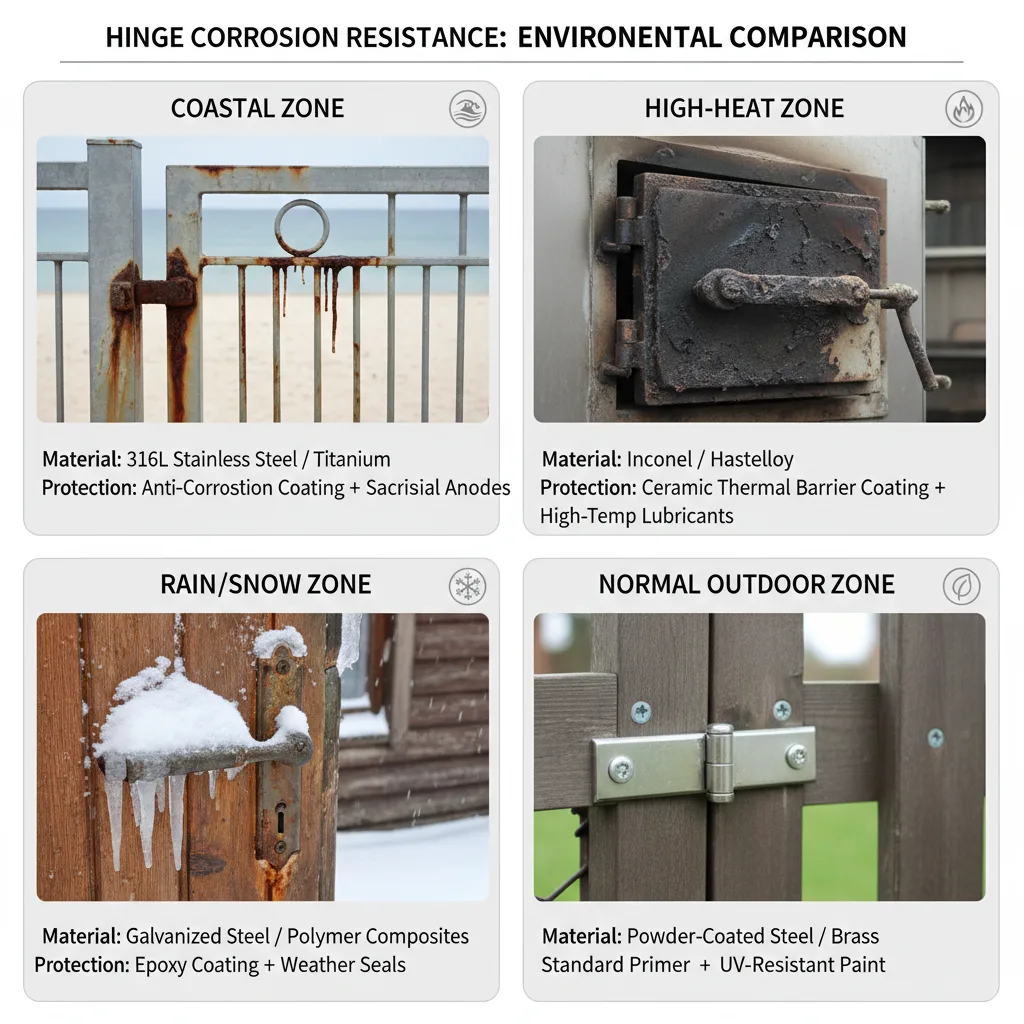

Rust Prevention Recommendations for Different Environments

Rust Prevention Recommendations for Different Environments

Coastal Areas

High salt content in the air creates strong corrosion. Prioritize 316 or higher-grade stainless steel hinges, with sealed welds and repainted surfaces. 316 stainless steel contains molybdenum, significantly enhancing resistance to chloride corrosion. Keep hinge surfaces seamless and regularly lubricate to prevent salt spray penetration.

High-Temperature Environments

Elevated temperatures accelerate coating degradation and may cause plating to peel. Opt for heat-resistant materials or coatings, such as steel hinges with high-temperature powder coatings or spray finishes. Avoid standard galvanized coatings—zinc oxidizes and melts at high temperatures, losing its protective function. For extreme heat, consider hinges made from specialized alloys (e.g., high-temperature stainless steel, chromium-silicon alloys) paired with dedicated heat-resistant lubricants.

Rain and Snow Regions

These areas frequently encounter snowmelt and road salt. A common solution combines hot-dip galvanized steel hinges with epoxy/polyurethane coatings, supplemented by periodic spray lubrication. The zinc coating sacrifices itself to protect the steel, while the coating seals out rainwater; lubricating grease prevents direct metal contact with pooled water. Inspect coating integrity every 6–12 months, reapplying rust-proof paint as needed. Clean and oil hinges during spring snowmelt.

Outdoor Fences/Gates

Carbon steel weld-on hinges are most common. Ensure quality welding and apply powder coating or galvanization. Combining powder coating with galvanization provides dual protection. For critical security doors, cast alloy hinges with waterproof covers enhance strength and weather resistance. During installation, ensure sufficient drainage clearance between hinges and the ground to prevent rainwater from flowing back into the door.[AISC Duplex Systems PDF]

Summary: Systematic Rust Prevention, from Material Selection to Maintenance

In summary, rust prevention for outdoor weld-on hinges is a systematic endeavor requiring comprehensive measures from material selection to routine maintenance. Choose corrosion-resistant materials or apply thicker protective coatings; control heat input during welding and apply protective coatings afterward; ensure proper drainage and sealing during installation; perform regular cleaning, repainting, and lubrication during use. Prevention is better than cure: Designing robust protective coatings and maintenance schedules in advance significantly extends hinge lifespan and prevents structural hazards caused by rust. Readers are advised to develop tailored rust prevention plans based on their specific environments, conducting regular inspections and maintenance to stay ahead of potential issues.

FAQ

Q1: Do stainless steel weld-on hinges still require rustproofing?

Yes. While stainless steel resists corrosion, the high temperatures of welding can damage its surface passivation layer, compromising the rust resistance of welds and surrounding areas. Therefore, even stainless steel hinges should undergo weld cleaning, acid pickling and passivation, or rustproof coating application post-welding to restore corrosion resistance.

Q2: How often should outdoor hinges be repainted?

Conduct a comprehensive inspection every 1–2 years to determine if repainting is needed. More frequent checks and maintenance are required in harsher environments (e.g., coastal areas or regions with heavy rain/snow). Typically, inspect hinge coatings every 12–18 months for cracks or peeling, and repair promptly. Long-term observation will help determine the optimal maintenance cycle.

Q3: Can rust spots be repaired once they appear?

Minor rust can be addressed by sanding and applying rust-inhibiting paint. First, remove surface rust with sandpaper or a wire brush, then seal the area with varnish or rust inhibitor. If severe rust has compromised the hinge structure, replace it promptly to prevent further damage.

Q4: Which rust-preventive oil is best for outdoor use?

Water-resistant synthetic lubricants are recommended. Examples include lithium-based grease or PTFE (Teflon)-containing lubricant sprays. These form a stable oil film on hinge surfaces, preventing direct contact between moisture/salt and metal to effectively delay corrosion.

Learn more about common weld-on hinge issues and quick solutions