Securing Public Infrastructure: Why Outdoor Cabinets Require Concealed Hinges

This article provides an in-depth engineering analysis of the critical role Concealed Hinges play in the security of public facility enclosures. We examine how this hardware solution mitigates specific risks defined in EN 1627 (physical attacks) and ISO 9223 (environmental corrosion). Based on field failure data and internal testing, we provide a quantifiable selection guide ranging from material science to load calculations.

Introduction

In the telecommunications, transportation, and utility sectors, outdoor cabinets—such as 5G base stations, automated ticketing machines, and roadside distribution boxes—are frequently deployed in unmonitored environments. These units house high-value electronic components yet face constant, severe security threats.

Based on our industry observations, threats to public facility cabinets primarily stem from two sources:

- Human Vandalism & Theft: Targeted physical attacks using leverage tools (crowbars), drills, or angle grinders.

- Environmental Erosion: Structural degradation caused by extreme weather, which exponentially weakens the cabinet’s physical defenses over time.

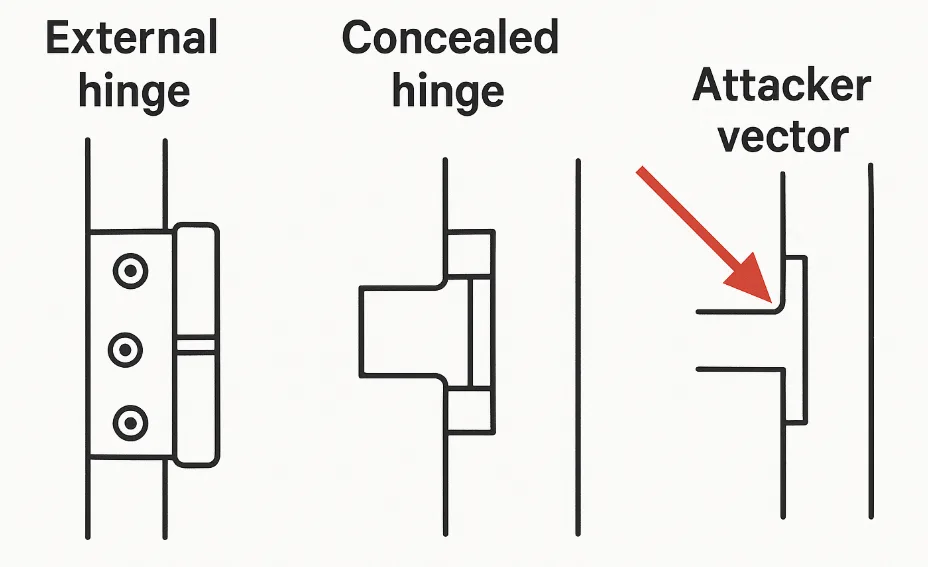

In traditional cabinet design, exposed hardware—specifically external hinges—is statistically the “weakest link.” An attacker need only cut the external pin to bypass complex multi-point locking systems entirely.

Introducing Concealed Hinges is not just an aesthetic choice; it is the critical technical path to resolving this systemic vulnerability.

This article serves as a technical guide for industrial designers and procurement managers. We will dissect the mechanics of concealed hinges, prove their advantages using comparative data, and provide standardized selection criteria.

Security Challenges and Vandal-Proof Requirements

When designing outdoor cabinets, we must first quantify the risks. According to field failure analysis, cabinet breaches often begin with the structural collapse of the hinge system.

Physical Attack Risks: From Crowbars to Cutting

Traditional external hinges expose mounting screws and pins to the attacker.

- Pin Destruction: Attackers use hydraulic shears or hacksaws to cut the pin. Once the pin is severed, the door detaches on the non-locking side.

- Fastener Removal: If external hinges use standard screws, a simple screwdriver allows for unauthorized disassembly.

Expert Insight: For public facilities, the design goal is to meet EN 1627 Class RC3. This requires the cabinet to withstand a sustained attack using crowbars and screwdrivers for a minimum of 5 minutes. External hinges often fail this test in under 60 seconds.

Environmental Corrosion Risks: The Invisible Strength Killer

Corrosion is a safety issue, not just an aesthetic one.

- Crevice Corrosion: Rainwater and salt spray accumulate at the interface between the external hinge and the cabinet body.

- Strength Degradation: Ordinary carbon steel in coastal environments (ISO 9223 Category C4) can lose structural integrity rapidly.

- Data Point: Material science principles indicate that improper materials can suffer a critical reduction in load capacity after prolonged exposure to salt spray (simulated by ASTM B117). A corroded hinge loses its ductility, becoming brittle and prone to shattering under impact.

- Pro Tip: Always request a Third-Party Salt Spray Test Report (from accredited labs like SGS or TUV) to verify the corrosion resistance of the hinges you intend to procure.

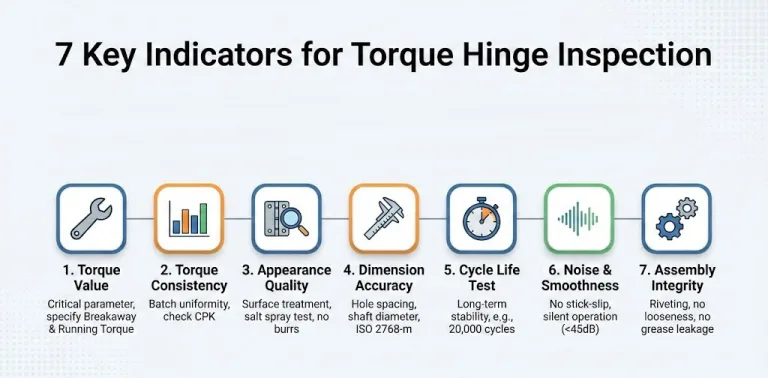

Key Metric: IK Protection Rating

When evaluating impact resistance, the IK10 rating (per IEC 62262) is mandatory.

- Definition: The enclosure must withstand a direct impact from a 5kg steel hammer dropped from 400mm (20 Joules).

- Implication: If the hinge acts as a fulcrum and snaps, the cabinet fails. Concealed designs, with load points located internally behind the steel frame, inherently pass this test with higher margins.

Technical Definition and Working Principles

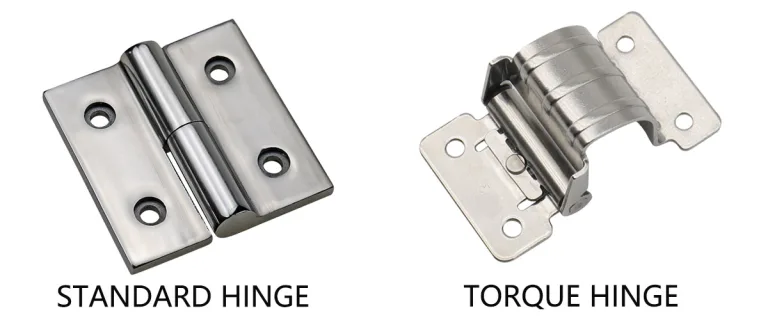

What is a Concealed Hinge?

A Concealed Hinge (or Industrial Internal Hinge) is a connection component where the mounting body is located entirely between the cabinet frame and the door return. When closed, no components are visible or accessible from the exterior.

Structural Design Types

U-Pin Structure

- Mechanism: Uses a U-shaped bent steel plate or casting pivoting around an internally fixed pin.

- Application: High-load scenarios where simplicity and durability are paramount.

Multi-link Mechanism (7-Bar)

- Motion Trajectory: Allows the door to translate outward (“throw”) before rotating.

- Advantage: Critical for cabinets with thick foam seals, preventing the door edge from binding against the frame.

Quick-Release & Spring-Loaded

- Operation: Features a retractable pin accessible only from the inside.

- Benefit: Allows tool-less door removal for maintenance, but only after the door has been legitimately unlocked.

Comparative Analysis: External vs. Concealed

| Assessment Dimension | Traditional External Hinge | Concealed Hinge | Advantage Analysis |

| Security | Pin exposed; cut time < 60s | Fully hidden; no attack point | Increases intrusion time significantly |

| Sealing | Requires cutting the gasket | Located inside the gasket | Ensures IP65/IP66 compliance |

| Vandalism | Vulnerable to prying | Protected by door steel | Force is transferred to the frame |

| Max Opening | 180° – 270° | 90° – 120° (standard) | External offers wider access |

Core Advantages in Vandal-Proof Design

Eliminating External Attack Points: Time is Safety

In security engineering, the objective is to prolong attack time.

- The Reality: Destroying an exposed hinge is a low-noise, low-effort task.

- The Concealed Advantage: With internal hinges, an attacker must cut through the 1.5mm – 2.0mm steel door skin to access the hardware. Field simulations show this increases the effort required to breach the hinge side from seconds to over 5 minutes, typically deterring the attempt or triggering sensors.

Enhancing Sealing Performance (IP65/IP66)

For outdoor applications, water ingress causes electrical shorts.

- The Problem: External hinges often require drilling through-holes or interrupting the foam seal strip.

- The Solution: Concealed hinges are mounted on the interior of the sealing perimeter. This allows for a continuous, uninterrupted sealing line.

- Standard Compliance: This continuity is often the deciding factor in passing NEMA 4X or IP66 (powerful water jet) certification tests.

Preventing Unauthorized Disassembly

This creates a logical security loop.

- Mechanism: The mounting screws are blocked by the door frame when closed.

- Result: It is physically impossible to unscrew the door without first defeating the main lock. This eliminates the “lock bypass” vector entirely.

Materials Science: Selecting the Right Hinge Material

Based on ISO 9223 corrosion categories, we recommend the following selection protocol:

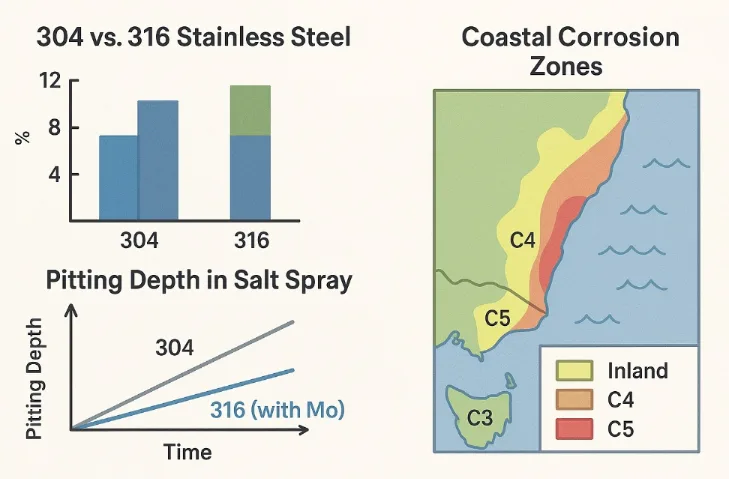

Stainless Steel (304 vs. 316)

- 304 Stainless Steel (AISI 304):

- Environment: Urban inland, industrial areas (C3 Corrosivity).

- Performance: Sufficient for standard outdoor use.

- 316 Stainless Steel (AISI 316):

- Environment: Coastal regions, chemical plants, offshore (C4/C5 Corrosivity).

- Technical Basis: The addition of 2-3% Molybdenum significantly improves resistance to pitting corrosion caused by chlorides (salt).

- Pro Tip: For installations within 5km of a coastline, 316 is mandatory. Our data shows 304 can develop structural rust within 12-24 months in these zones.

Carbon Steel (Zinc/Nickel Plated)

- Risk: Once the plating is scratched (common during installation), the base metal oxidizes rapidly.

- Verdict: Not recommended for critical infrastructure requiring a 10+ year lifespan.

Zinc Alloy (Die-Cast)

- Limitation: While cost-effective, Zinc Alloy has lower tensile strength and is brittle.

- Warning: In IK10 impact testing, Zinc Alloy hinges are significantly more likely to fracture than Stainless Steel. Use only for smaller, lower-risk enclosures (Door weight < 20kg).

Application Scenarios: Deployment of Concealed Hinges

- Telecom (5G/Fiber):

- Focus: Sealing. Must pass 960-hour salt spray tests to ensure the hinge does not seize, protecting high-heat electronics.

- Transportation (Rail/Highway):

- Focus: Vibration. We recommend hinges with POM (Polyacetal) bushings. This prevents metal-on-metal fretting corrosion caused by the high-frequency vibrations defined in IEC 61373.

- Financial (ATM/Kiosk):

- Focus: Brute Force. Must use heavy-duty 304/316 Steel. Design with a multi-point layout (3-4 hinges) to distribute pry-bar loads.

Selection Guide: How Engineers Should Choose

Load Calculation and Safety Factor

Do not rely on static weight estimation alone.

- Calculation: Total Door Weight + Mounted Equipment.

- Safety Factor: We recommend a Safety Factor of 1.5 to 2.0.

- Why? To account for Dynamic Loading (wind gusts up to 120km/h) and potential misuse (technicians leaning on the door).

- Example: For a 40kg door, the hinge set should be rated for 60kg-80kg.

Opening Angle and Maintenance

- 90° vs. 120°: If the cabinet contains slide-out rack servers, a 90° opening is insufficient. Ensure the hinge geometry allows for at least 120° clearance.

3D Modeling and Interference Checks

Because the “throw” of a concealed hinge is complex, 2D drawings are prone to error.

- Best Practice: Always Always import the specific STEP file into your CAD assembly (e.g., SolidWorks) and run a collision detection simulation. You can download these 3D models directly from the specifications tab on our [Concealed Hinge Product Pages]

Conclusion

In public facility infrastructure, security is a core function, not a feature. Transitioning from external hardware to Concealed Hinges fundamentally eliminates the most common physical attack vector, ensures IP66 compliance, and extends service life in corrosive environments.

Industry Action:

As the deployment of distributed infrastructure (5G, EV charging) accelerates, the standard for enclosure security is rising. We strongly advise engineering teams to incorporate concealed hinge specifications during the Concept Design Phase. Retrofitting internal hinges into a finalized sheet metal design is costly and often technically compromised. Start with the right hardware to build an impenetrable defense.