Adjustable vs. Constant-Torque Hinges: Selection and Adjustment Guide

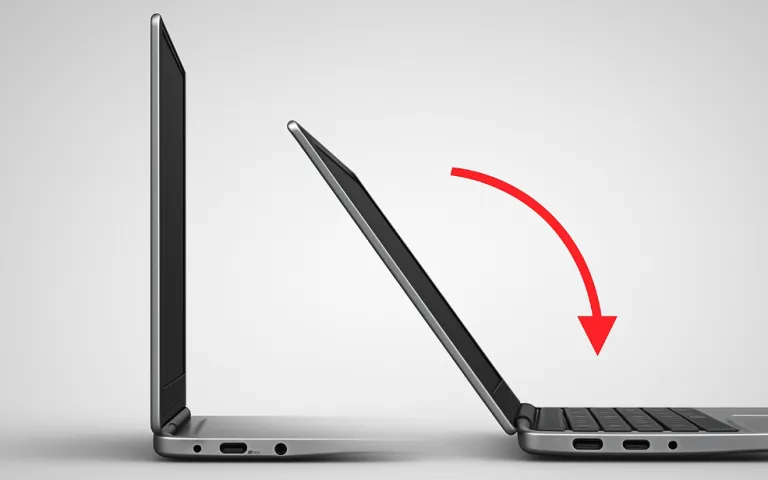

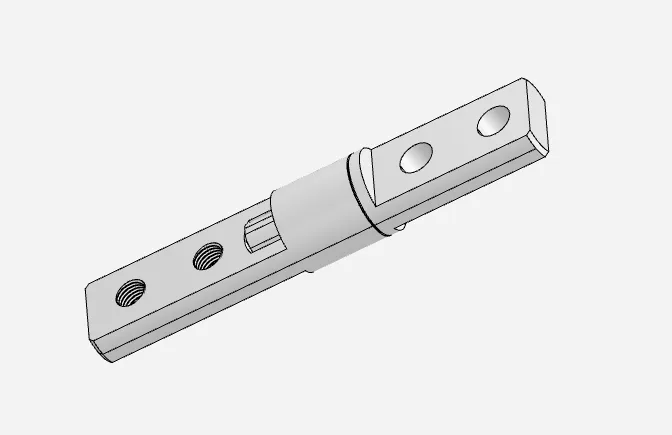

Torque hinges (also known as friction hinges or positioning hinges) generate controlled resistance through internal friction damping, allowing screens or covers to remain at any angle. They are widely used in laptops, medical devices, and industrial equipment. Torque hinges are mainly divided into adjustable and constant-torque types: the former allows users or technicians to modify the damping level, while the latter is preset at the factory and cannot be changed. Selecting the appropriate hinge type can significantly improve product feel and reliability.

Overview of Torque Hinges

Torque hinges use friction plates, springs, and other components to generate damping torque, enabling smooth movement and position holding at any angle. Torque, measured in N·m, is the key indicator of “tightness.” Common applications include consumer-electronics displays, medical-device arms, industrial access doors, furniture flip panels, and transportation interiors. Different industries have varying requirements for torque values, lifespan, and materials.

Adjustable Torque Hinges

Working Principle

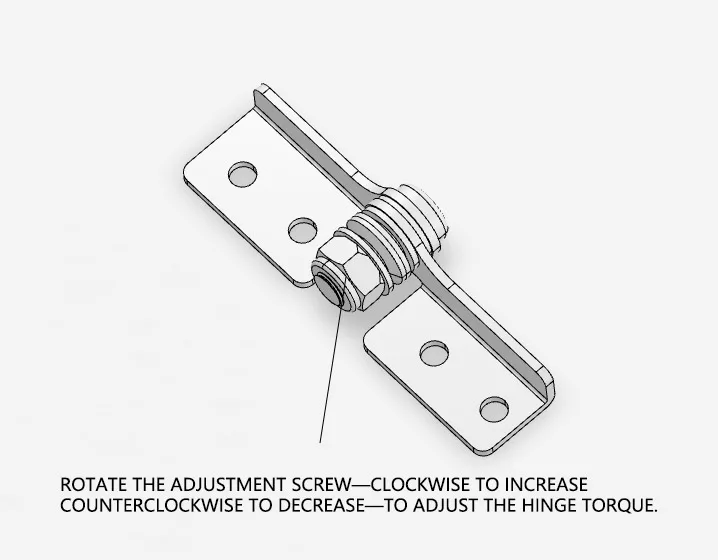

Adjustable hinges contain a torque adjustment screw that changes the clamping force of the friction components, thereby altering resistance. Turning clockwise increases torque; turning counterclockwise decreases it.

Main Features and Advantages

- Torque adjustability: wide applicability; a single hinge can suit different loads and user preferences.

- Strong maintainability: torque loss over time can be compensated by tightening.

- Helpful for R&D: convenient for prototypes requiring frequent adjustments.

- Adapts to load changes: increased or decreased load can be matched by adjusting torque.

Limitations

- Requires tools, making it difficult for everyday users.

- Because the adjustment is manual, maintaining consistent torque among multiple hinges is challenging.

- More complex internal structure, and lifespan may be slightly shorter than constant-torque types.

Constant-Torque Hinges

Working Principle

Constant-torque hinges are preset at the factory and cannot be adjusted. They provide stable damping throughout the full range of motion.

Features and Advantages

- Consistent feel: each hinge is factory-calibrated.

- Simple and reliable structure: no adjustment mechanism, offering high long-term stability.

- Low maintenance: requires no adjustment after installation, suitable for mass production.

Limitations

- Fixed torque—hinges must be replaced if requirements change.

- Not suitable for applications where loads change frequently.

- Initial selection must be accurate; replacement cost may be high later.

Comparison Between the Two Types

| Item | Adjustable Torque | Constant Torque |

|---|---|---|

| Adjustment capability | Adjustable | Fixed, not adjustable |

| Stability | Influenced by manual adjustment | Highly consistent and stable long-term |

| Maintainability | Requires periodic calibration | Nearly maintenance-free |

| Application scenarios | R&D, variable loads, customized feel | Mass production, fixed requirements |

| Cost | More complex structure, slightly higher | Cost-effective, long lifespan |

Summary: Adjustable hinges suit uncertain or changing requirements; constant-torque hinges suit mass-produced products needing consistent user experience.

Suitable Scenarios for Adjustable Hinges

- R&D stages requiring rapid damping adjustments.

- Situations where equipment weight will change (such as adding accessories or tools).

- Applications requiring user-customizable feel (such as high-end monitor arms or photography equipment supports).

- Environments where loads change (such as outdoor stands affected by wind).

Suitable Scenarios for Constant-Torque Hinges

- Mass-produced standardized products (such as laptops or home appliances).

- Scenarios requiring unified brand feel.

- Devices where users should not adjust internal mechanisms (such as medical instruments), especially those requiring plastic components or other materials to meet ISO 10993 biocompatibility testing or achieve USP Class VI medical-grade certification.

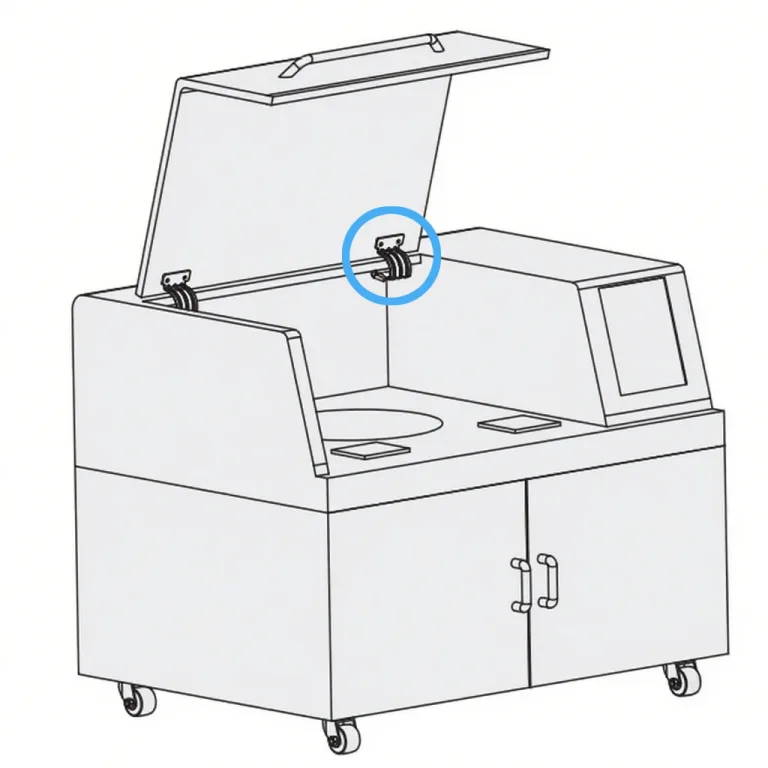

- Stable environments emphasizing long-term reliability (such as industrial cabinet doors).

Torque Adjustment Method for Adjustable Hinges

Preparation Before Adjustment

- Confirm rated torque range and adjustment limits.

- Inspect hinge condition and screw condition.

- Use proper tools (preferably torque-controlled tools).

Adjustment Steps

- Locate the adjustment screw.

- Make small incremental adjustments: clockwise to increase, counterclockwise to decrease.

- Test after each adjustment to avoid large one-step changes.

- After reaching the desired torque, tighten the locknut (if present).

Post-Adjustment Calibration

- Perform multi-angle holding tests to ensure uniform damping.

- Conduct simulated load testing.

- Record screw position for future maintenance.

Common Issues and Solutions

- Insufficient torque: increase torque; replace hinge if still insufficient.

- Excessive resistance: loosen the screw or use a lower-torque model.

- Screw loosening: tighten periodically; apply thread-locking adhesive if necessary.

- Worn friction surfaces: repair or replace the hinge.

Key Parameters for Hinge Selection

Torque Value

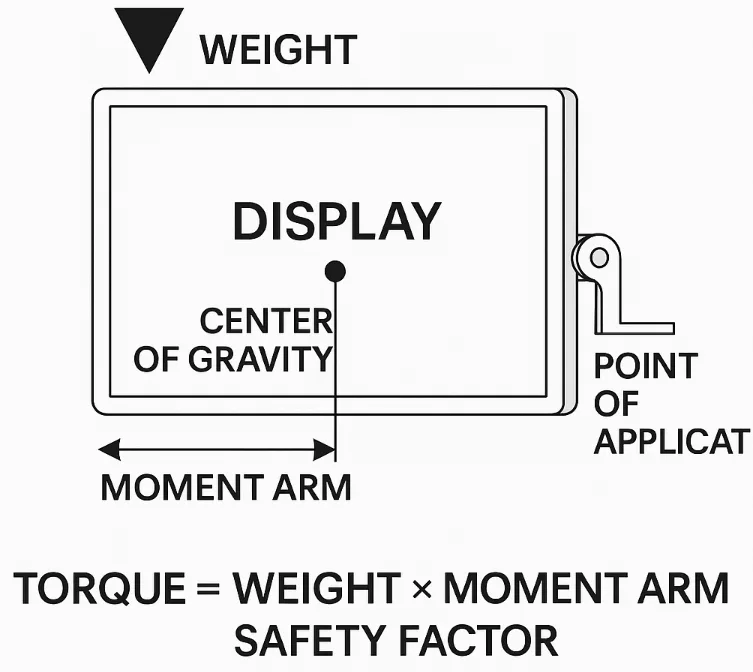

Torque ≈ Weight × Moment arm × Safety factor (1.2–1.5).

Use manufacturer torque charts and reserve about 30% safety margin.

Lifespan and Durability

Typical lifespan is 10,000–50,000 cycles; high-end models exceed 100,000.

Torque decay (“looseness”) after rated cycles should be ≤20%.

Durability evaluation can reference relevant industry standards such as EN 1935 (European single-axis hinges) or ANSI/BHMA A156.17 (North American furniture hardware).

These standards define testing procedures for cycle life and torque decay.

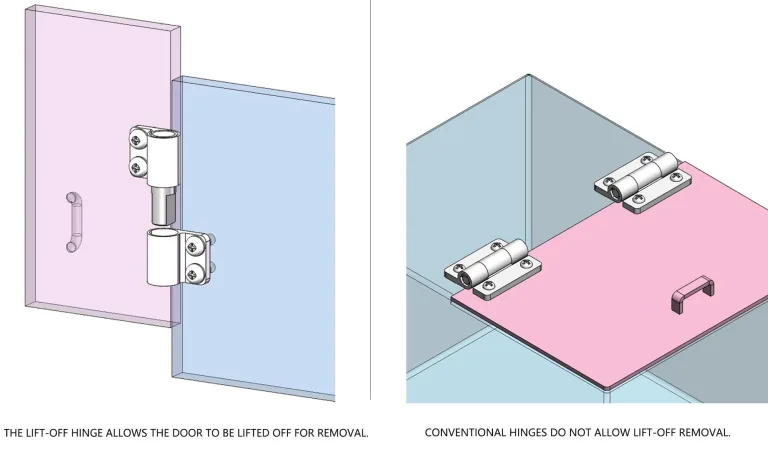

Installation Method and Dimensions

Choose surface-mount or concealed hinges; consider shaft diameter, length, hole spacing, and screw type.

Multi-hinge systems must be precisely aligned.

Environmental Factors

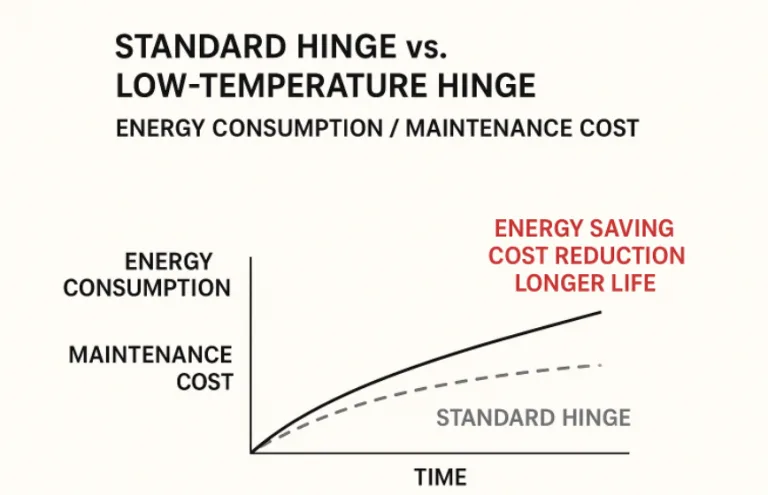

- Temperature: extreme temperatures require special lubricants and materials.

- Humidity/Corrosion: choose stainless steel (such as SUS304) or coated hinges.

Corrosion resistance is typically validated by neutral salt-spray tests (ASTM B117 or ISO 9227); For certain coating systems, achieving ≥240 hours without significant corrosion is often used as a benchmark for acceptable performance.

For dust/water protection, check whether the hinge meets IP ratings (IEC 60529). - Vibration: in vehicles or heavy machinery, hinges must maintain torque and structure.

Reliability can be verified using IEC 60068-2-6 or MIL-STD-810.

Maintenance Guide

- Periodically inspect damping feel, screws, wear, and alignment.

- Clean with a dry cloth or alcohol; avoid water contact.

- Lubricate carefully with manufacturer-approved grease; avoid regular machine oil/grease.

- Recommended intervals: clean every 6 months; lubricate every 12 months (or more frequently for heavy-use devices).

Common Misuse Issues

- Selecting excessive torque, causing difficulty in operation.

- Material and environment mismatch (e.g., using regular steel outdoors).

- Improper screw adjustment causing damage.

- Overloading without upgrading hinge torque.

Conclusion

Adjustable hinges provide flexibility for variable loads and iterative development; constant-torque hinges offer stable, consistent performance for mass-produced products.

Hinge selection should comprehensively consider torque requirements, lifespan, installation, and environmental conditions.

Proper adjustment and maintenance are key to ensuring long-term stability and improving product performance.