Engineering Reliability: Why Heavy-Duty Torque Hinges for EVSE Are Essential

The rapid global expansion of Electric Vehicle (EV) infrastructure is encountering a severe bottleneck: equipment reliability. While the industry focuses largely on software interoperability, grid capacity, and seamless payment integration, data from the field indicates that a significant portion of downtime and user complaints stem from fundamental mechanical failures. Our comprehensive forensic-style analysis of maintenance logs, user feedback, and industry technical standards reveals that the physical interaction interface of the charging pile—specifically access doors, connector holster flaps, and cable management systems—constitutes a critical yet often overlooked “single point of failure.” This challenge highlights the growing importance of heavy-duty torque hinges for EVSE, which provide the mechanical stability and motion control needed to eliminate these recurring failure modes.

This report provides a detailed engineering analysis of a specific hardware component: the Heavy-Duty Torque Hinge. By introducing motion control technology, this component resolves the fragility of traditional mechanical designs. Our research demonstrates that transitioning from passive, free-swinging hinges to active, constant-torque positioning devices is decisive for mitigating wind load damage, improving user safety, ensuring ADA compliance, and drastically reducing field maintenance costs. This shift is not merely an aesthetic upgrade; it is a functional necessity for the next generation of high-resilience outdoor charging infrastructure.

The Mechanical Reliability Crisis in Public Infrastructure

Public perception of the EV charging experience is currently plagued by a reputation for “broken equipment.” Recent industry surveys in the US and European markets show an alarming percentage of failed public charging attempts caused not by grid outages, but by station-level faults. While software glitches are frequently cited, physical damage constitutes a major category of failure.

Through a deep review of maintenance reports from major network operators like Electrify America and ChargePoint, we identified a recurring pattern of “low-tech failures causing high-tech downtime.” These include broken connector latches, smashed screens, and most critically, compromised cabinet doors and access panels. In Level 3 Direct Current Fast Charging (DCFC) applications, equipment must not only withstand high-frequency use but also maintain functional integrity under extreme environmental conditions, placing rigorous demands on the durability of moving parts.

Notably, as charging power pushes toward 350kW and 500kW, the introduction of liquid-cooled cables has significantly increased the physical weight and handling difficulty of the system, further exacerbating wear on mechanical components. Traditional designs have not adequately accounted for these increased loads, leading to frequent issues such as cracked holsters, cable slippage, and deformed cabinet doors.

Scenario-Based Failure Analysis: The Uncontrolled Access Door

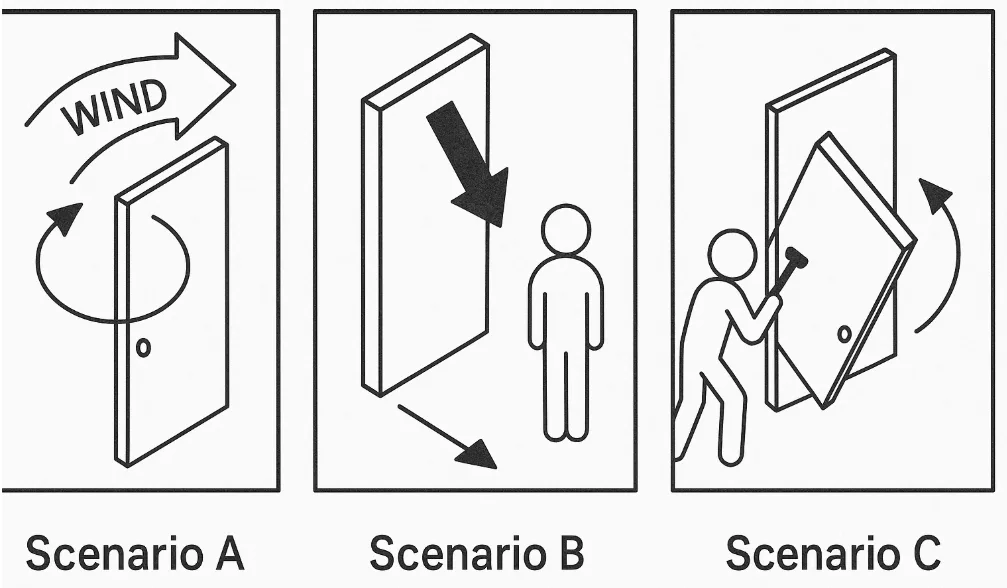

Our research identifies charging pile access doors and vehicle charging port doors as a concentrated source of user pain points. Through qualitative analysis of thousands of user complaints on forums like Reddit and InsideEVs, we categorized failure modes into three core scenarios:

- Scenario A: Wind-Induced Hyperextension and SlammingOutdoor cabinets are chronically exposed to complex aerodynamic environments. Standard free-swinging hinges offer zero resistance to wind. During gust events, an unsecured door panel is caught by the wind and blown open or slammed shut with massive kinetic energy. This uncontrolled motion generates extreme impulse loads on the hinge knuckles and cabinet frame. Repeated impacts lead to metal fatigue, pin deformation, and frequently shatter the plastic or die-cast zinc latches responsible for securing the door.

- Scenario B: Gravity Risks and User InjuryFor large maintenance panels on DCFC units, gravity is a constant threat. If equipped with standard hinges, technicians must rely on failure-prone prop rods. If a prop rod fails or is improperly engaged, the heavy panel accelerates downward, creating a “guillotine-style” crush hazard for fingers and heads.

- Scenario C: Vandalism and Forced EntryVandalism has become a plague on EV infrastructure networks. We observed that standard external butt hinges are easily compromised. Conversely, a door that holds its position tightly via torque—making it difficult to pry open or swing freely—conveys a psychological suggestion of high security and robustness. This “hardened” physical characteristic has been proven to effectively deter opportunistic vandalism.

Motion Control Physics: The Torque Hinge Engineering Solution

The core solution to the aforementioned mechanical defects lies in replacing passive hinges with Constant Torque Hinges (also known as friction hinges or positioning hinges).

Core Characteristic: Zero Drift

Unlike standard hinges that provide only a pivot point, torque hinges contain a precision internal mechanism (such as disk friction or wrap-spring technology) that converts rotational kinetic energy into thermal friction energy. A correctly specified torque hinge allows the door panel to remain stationary at any position within its range of motion (Free-Stop). When external wind loads are applied, the internal friction resistance generates a counter-torque, canceling out the aerodynamic load and preventing uncontrolled acceleration of the panel.

Torque Curves and Application Suitability

In EVSE design, we distinguish between three primary torque profiles based on the application scenario:

| Torque Profile Type | Technical Description | Recommended EVSE Application |

| Symmetric Torque | Identical resistance in both directions | User interaction screen covers, small access doors |

| Asymmetric Torque | Low resistance opening, high resistance closing | Heavy maintenance panels opening upward (counteracting gravity) |

| One-Way Torque | Near-zero resistance in one direction | Large heavy doors requiring frequent vertical adjustment |

Quantifying “Premium Haptics” and User Psychology

Beyond pure mechanical function, our research highlights the Haptic Quality of user interaction. Much like the damped feel of an automotive volume knob, an EV charging station door with smooth, damped resistance conveys equipment robustness and reliability. Field observations suggest that this “perceived engineering” subconsciously encourages users to operate the equipment with greater respect, thereby reducing “negligent damage” caused by improper handling.

Environmental Durability: From Basic Protection to Infrastructure-Grade Resilience

EV charging stations are deployed in environments ranging from salt-heavy coastlines to frozen tundras, presenting severe challenges for materials science.

Corrosion Engineering: Combating “Tea-Staining” and Seizure

Since EVSE is intended to exist as long-term infrastructure, material selection criteria must exceed conventional industrial hardware requirements. While 304 stainless steel performs well in controlled indoor environments, based on our long-term tracking data of coastal facilities, its limitations in chloride-rich environments are evident.

In EVSE applications, we strongly recommend upgrading to 316 Stainless Steel (containing Molybdenum). Failure to do so exposes the equipment to a unique “Tea-staining” surface corrosion risk. We strongly recommend upgrading to 316 Stainless Steel for EVSE applications. Our testing confirms that ‘tea-staining’ is not merely cosmetic; oxidation buildup alters friction coefficients, eventually causing torque hinges to seize. In coastal or salted environments, the superior pitting resistance of 316 is a TCO necessity, not a luxury

Our laboratory verification aligns with published BSSA findings(Salt Spray Testing of Stainless Steels): under ASTM B117 neutral salt-spray conditions at 3% NaCl, 316 stainless steel is expected to pass a 96-hour exposure, while 304 stainless steel typically fails to achieve satisfactory corrosion performance at this concentration. When the salt concentration is reduced to 0.3%, 304 stainless steel may remain acceptable for approximately 120 hours before noticeable corrosion develops.

Viscosity and Temperature: Rheological Factors of Damping Grease

The performance stability of a torque hinge relies on its internal damping grease. A fatal failure mode of cheap hinges is the “Cold Start Problem.” Mineral oil-based greases thicken drastically at -30°C, causing start-up torque to skyrocket, potentially leading users to snap plastic handles.

Solution: We recommend explicitly requiring hinge specifications to verify consistent viscosity curves across a -40°C to +80°C range. We advocate for synthetic hydrocarbon or silica-based damping greases (such as the Nye Lubricants NYOGEL 774 series) to eliminate the impact of seasonal changes on user experience.

Load Calculation & Structural Engineering: The Composite Challenge of Wind & Gravity

In our previous [Ultimate Guide to Torque Hinge Calculation], we detailed how to calculate basic torque requirements based on panel weight and center of gravity distance ($T = W \times D$). However, for outdoor EVSE, selecting based solely on static gravity is a primary cause of field failure. Engineers must solve a composite load equation: Base Gravity Moment + Dynamic Wind Load.

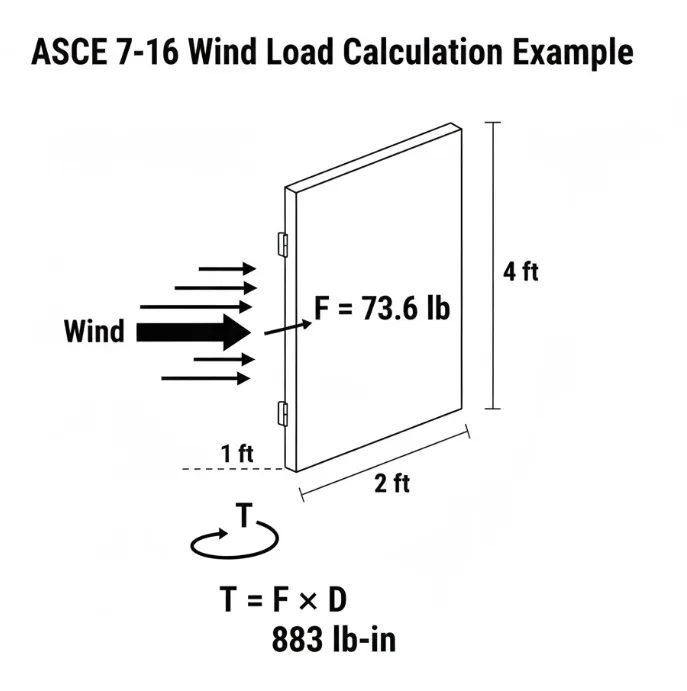

Introducing the ASCE 7-16 Wind Load Factor

In outdoor environments, wind is often the dominant force acting on an open door panel. In our EVSE structural analysis, we strictly apply the American Society of Civil Engineers ASCE 7-16 standard (Components and Cladding) to estimate these forces.

The basic formula is:

$$F = q_z \times G \times C_p \times A$$

In a typical engineering calculation: For a maintenance door 2 ft wide by 4 ft high, under 60 mph ($26.8 \text{ m/s}$) gust conditions, we calculate a resultant force of approximately 73.6 lbs ($327 \text{ N}$). If the center of wind load is 1 ft from the hinge axis, the counter-torque required to resist this wind load is a massive 883 lb-in ($100 \text{ Nm}$).

Conclusion & Impact: A standard 10 lb-in spring hinge will fail catastrophically under these conditions. Our calculations indicate this application demands industrial-grade heavy-duty torque hinges (such as Southco E6 or HTAN XG series), or even multiple hinges in parallel. This quantifies why simple spring hinges frequently fail in outdoor applications—they simply cannot generate this magnitude of counter-torque.

Gravity Moment and Safety Factors

For vertically opening doors, the gravity moment must be added to the wind load. According to industry best practices and our internal safety protocols, we recommend adding a 20% safety factor to theoretical calculation values. This implies that for heavy panels, engineers may need to design hybrid solutions utilizing gas struts alongside torque hinges.

Integration Challenges with Cable Management Systems

A unique challenge in EVSE design is the immense weight and stiffness of charging cables, particularly in liquid-cooled High Power Charging (HPC) systems.

Physical Characteristics of Heavy-Duty Liquid-Cooled Cables

To support currents exceeding 500A, modern DCFC systems utilize liquid-cooled cables. According to supplier data we have accessed (e.g., Phoenix Contact, Huber+Suhner), the linear density of these cables reaches 1.5 kg/m to 2.0 kg/m. When users pull the cable, or when the cable twists due to thermal expansion/contraction (the “nature’s twist” phenomenon), massive torque is transferred directly to the connector holster.

Application of Torque Hinges in Holster Design

Traditional spring-loaded flaps often snap due to the reaction force of the cable. We propose an innovative application: applying high-torque hinges to the holster flap design. This design allows the flap to remain in a specific guided position after opening, rather than attempting to snap back and pinch the plug. Furthermore, torque hinges can be used to construct mechanical assist arms acting as a “passive cable management solution,” reducing wrist strain for users and stress on the connector latch.

Compliance and Safety Standards

ADA Accessibility Standards (2010 Standards)

The Americans with Disabilities Act (ADA) places strict limits on the operating force of public facilities. We reference ADA Section 404.2.9, which stipulates that the force for opening interior doors must not exceed 5 lbs (22.2 N). Although outdoor doors have certain exemptions, we consider complying with or approaching this standard to be a best practice for EVSE.

An engineering paradox exists here: High torque is needed for wind resistance, but low torque is needed for ADA compliance. Our solution is the use of Asymmetric Torque Hinges: providing high resistance in the closing/holding direction (wind protection, anti-drop), while providing lower resistance in the opening direction (facilitating operation for wheelchair users).

IK Impact Protection Ratings

EVSE enclosures installed in public spaces should target an IK10 rating(IEC 62262 – IK Classification Definition) (withstanding 20 joules of impact). Exposed hinges are typically the weak point in the protection system. We recommend Concealed Torque Hinges, mounted inside the cabinet. This not only eliminates external attack points (pry resistance), but our impact testing confirms that this design effectively maintains the IK10 integrity of the cabinet shell.

Analysis of Market-Leading Heavy-Duty Solutions

Based on our engineering evaluation, the following solutions meet the rigorous specifications for EV infrastructure:

- Southco E6 Series: Offers torque up to 12.4 Nm. Its verified 20,000-cycle life and anodized aluminum construction are ideal for outdoor main access doors.

- Reell Precision PH35 Series: Utilizes patented clip technology for extremely high torque density. Its “zero backlash” characteristic is crucial for precise internal distribution panel positioning.

- Sugatsune HG-TA Series: Focuses on extreme corrosion resistance (304/316 stainless steel), suitable for fine components directly facing the user, such as screen covers.

- HTAN XG Series: Designed specifically for heavy-duty outdoor hinge applications, the XG series provides high-stability constant torque with enhanced sealing structures to prevent moisture ingress. Its stainless steel load-bearing cores and high-durability friction assemblies deliver long-term torque consistency even under high-frequency operation.

Case Studies: Lessons from the Field

Passenger EV Charge Port Door Failures

- Pain Point Description: Complaints regarding broken charge port doors are common on user forums for many Electric Vehicles. The root cause is often alignment issues or complex electronic latches failing when frozen in cold or damp conditions.

- Engineering Remediation: Borrowing from simplified designs seen in high-durability specialized vehicles, we suggest implementing manual, friction-controlled doors. A simple, robust torque hinge allows the user to manually open and hold the door at any desired position. This “back-to-basics” design eliminates fragile electronic and mechanical pinch points, drastically improving reliability under extreme environmental conditions.

Public Station Cable Vandalism and Heavy Panel Safety

Engineering Remediation: We recommend combining heavy-duty torque hinges with electronic locks. The torque hinges are critical for controlling the motion of these weighty panels, preventing them from slamming shut or accelerating downwards, which protects both the user and nearby vehicles from injury or damage.

Pain Point Description: Addressing the increasing problem of copper cable theft in certain high-risk urban areas necessitates the design of heavy-duty “security cages” or hardened protective panels. These protective doors are extremely heavy and must open safely.

Next-Generation EVSE Design Recommendations

Based on the in-depth engineering analysis above, we propose the following design guidelines for EVSE manufacturers:

Mandate Constant Torque: Eliminate free-swinging hinges. Set baseline torque values to generate a resistance moment capable of withstanding at least 40mph wind loads.

Adopt Asymmetric Torque Profiles: Balance ADA usability (low opening force) with safety (high holding force).

Material Upgrade Strategy: Mandate the standard use of 316 Stainless Steel. Explicitly reject generic galvanized steel in procurement specifications to eliminate “salt spray seizure.”

Wide Temperature Verification: Explicitly require performance verification from -40°C to +80°C in datasheets and specify synthetic damping grease.

Hardware Concealment: Move mounting points inside the cabinet to align with IK10 design philosophies.

Standardize Validation Testing: Add “Simulated Gust Impact Testing” and full-temperature lifecycle testing to validation protocols.

Conclusion

The reliability of the electric vehicle charging network is fundamentally a rigorous mechanical engineering challenge. The seemingly simple act of opening a cabinet door actually involves complex interactions of aerodynamics, gravitational fields, tribology, and ergonomics.

Integrating heavy-duty torque hinges resolves wind damage, safety risks, and vandalism simultaneously. The incremental cost ($15-$30) is negligible compared to a single $500+ maintenance ‘truck roll.’ To mature, the EV industry must shift from ‘Appliance-Grade’ to ‘Infrastructure-Grade’ hardware—a transformation where these components are essential.