What Is Hinge Sag? Diagnosis, Repair, and Prevention Guide (ANSI Standards)

Quick Summary (Key Takeaways)

- Hinge Sag: A condition where a door or cabinet door shifts downward or becomes misaligned due to the loosening or wear of hinges, mounting points, or the substrate material after prolonged load-bearing and repeated use.

- Common Symptoms: Door dragging on the floor, failure to latch, uneven gaps (wider at the top, narrower at the bottom), latch misalignment, and uneven adjacent cabinet doors.

- Prevention Priority: Correct installation + selecting the right hardware load rating + periodic inspection of fasteners and reveal gaps (recommended every 6–12 months).

What Exactly Is Hinge Sag?

Definition and Mechanics (Simplified)

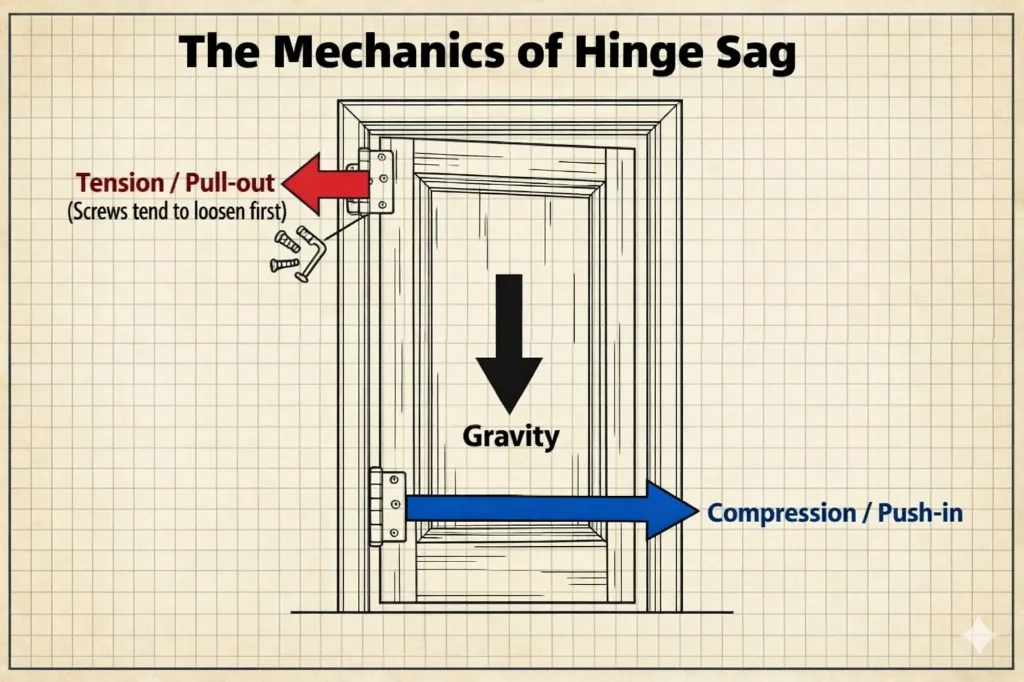

Hinges perform two primary functions: bearing weight and rotating around an axis.

The weight of the door is transferred through the hinges to the door frame or cabinet side panel.

- Mechanical Insight: The door’s weight creates Tension (pull-out force) on the top hinge, attempting to pull it away from the frame, while creating Compression (push-in force) on the bottom hinge. This explains why 90% of sag issues originate with the top hinge screws loosening.

When the hinge axis or mounting points shift, the center of gravity of the door exerts continuous strain on the fasteners. The result is typically door sagging, changing gap reveals, and latch misalignment.

For selection or inspection, hinge performance and durability are often referenced against industry standards, such as ANSI/BHMA A156.1 (Butts and Hinges), which outlines requirements for cycle counts, wear, and strength.

Common Types (By Scenario)

- Passage Door Sag (Interior / Exterior)

- Interior: Most commonly caused by loose screws or deformation of the wood screw holes.

- Exterior: Often caused by heavier door weight, or extra resistance from door closers and weather stripping systems.

- Cabinet Door Sag (Concealed Hinges / Butt Hinges)

- Concealed Hinges: Most are 3-way adjustable, but rely on the cabinet box being level and sufficient screw holding power.

- Material Issues: Low-density fiberboard is more prone to “stripped screws” and hole enlargement over time.

How to Diagnose Hinge Sag (Diagnostic Steps)

5 Typical Symptoms Checklist

- Uneven Reveal: The gap between the door and frame is wider at the top and tighter at the bottom.

- Rubbing/Dragging: The top corner rubs the frame, or the bottom corner drags on the floor.

- Latch Failure: The latch bolt does not align with the strike plate, or the door must be lifted to lock.

- Resistance: A “dragging” sensation or squeaking noise when opening/closing.

- Cabinet Misalignment: Adjacent cabinet doors are not level; vertical gaps are inconsistent.

3-Minute Self-Inspection Method

- Gap Consistency

- Slide a dollar bill or thin card along the perimeter of the closed door.

- Note areas where it binds tightly or slides too freely.

- Vertical Plumb Check

- Use a torpedo level to check if the door edge is plumb.

- Alternatively, use a plumb bob to check the deviation of the door edge against a vertical line.

- Hinge and Screw Status

- Check every screw for tightness.

- Inspect for stripped holes (screws that spin without tightening), metal dust (sign of heavy wear), or gaps between the hinge and the mortise.

Process of Elimination: Non-Hinge Issues

- Foundation settling or wall deformation.

- Uneven flooring or changes in threshold height.

- Seasonal expansion/contraction of wood doors due to humidity.

- Cabinet boxes not being leveled during installation (common in multi-door runs).

Common Causes of Hinge Sag (Ranked by Probability)

Installation Issues (Most Common)

- Insufficient Screw Length: Screws fail to bite into the stud, solid wood, or reinforcement backing.

- Poor Mortising: Incorrect mortise depth prevents the hinge leaf from sitting flush.

- Insufficient Quantity: Not enough hinges or poor spacing for the door’s height and weight.

- Mismatched Specifications: Inadequate load rating. Refer to ANSI/BHMA A156.1 grading and testing logic for proper selection.

Wear and Tear from Long-Term Use

- Vibration from frequent cycles gradually loosens screws.

- Wear on the hinge pin and knuckles increases the gap tolerance.

- Hanging heavy items (coats, bags) on the door increases torque.

Material and Environmental Factors

- Wood shrinkage/swelling reduces screw holding power.

- Humidity and corrosion degrade hardware strength.

- Low-density core materials expand screw holes under long-term load.

How to Fix Hinge Sag (Step-by-Step)

The following methods are organized by “Priority + Risk Control.” For exterior doors, fire doors, and egress doors, priority must be given to applicable codes and manufacturer instructions. Installation and maintenance of fire door assemblies typically reference NFPA 80 (Standard for Fire Doors and Other Opening Protectives).

Method Comparison Table

| Method | Use Case | Tools | Difficulty | Risk Factor | Est. Time |

| 1. Tighten & Re-align | Mild sag, screws still grip | Screwdriver/Driver | Low | Stripping screws if over-torqued | 10–30 Mins |

| 2. Longer Screws | Loose screws, hole not stripped | 3″ Screws, Driver | Low-Mid | Hitting wiring; Code check for fire doors | 15–45 Mins |

| 3. Repair Stripped Holes | Screws spin, no grip | Dowels/Toothpicks, Glue | Mid | Can loosen again if not centered | 30–90 Mins |

| 4. Shimming | Uneven gaps, hardware solid | Shims, Screwdriver | Mid | Altering stress/lock alignment | 20–60 Mins |

| 5. Replace/Upgrade | Heavy door, old/worn hinges | New Hinges | Mid-High | Hole deviation causes misalignment | 60–180 Mins |

Tightening and Re-alignment (First Priority)

- Check the top hinge (tension point) first, then the bottom hinge.

- Adjust the door to a relatively even reveal before final tightening.

- Re-test gap and latch alignment after tightening.

- Cabinet Doors (Concealed Hinges): Follow the “3-Way Adjustment” order:

- Vertical (Height)

- Horizontal (Side-to-side gap)

- Depth (In/Out flush with cabinet)

Replace with Longer Screws (For Structural Grip)

- Applicability: Screws are loose, but the hole location is still viable.

- Goal: Anchor the hinge into the structural framing (studs) rather than just the door jamb.

- Safety Warning (Critical): Before driving a 3-inch (76mm) screw, you must confirm there is no electrical wiring inside the wall stud (especially near light switches). Use a stud finder with voltage detection to avoid short-circuit risks.

- Note: For exterior, fire-rated, or panic doors, do not arbitrarily alter key connection methods. Maintenance of fire door systems requires compliance with NFPA 80 and consistency with the door/hardware manufacturer’s listing.

Repairing Stripped Holes

- Wood Doors/Solid Core:

- Fill with wood dowels/toothpicks + wood glue.

- Allow to cure, drill a new pilot hole, and reinstall screws.

- Composite/Metal Substrates:

- Select a larger gauge screw or use a thread repair kit depending on the material.

- The focus is restoring holding power and positioning accuracy.

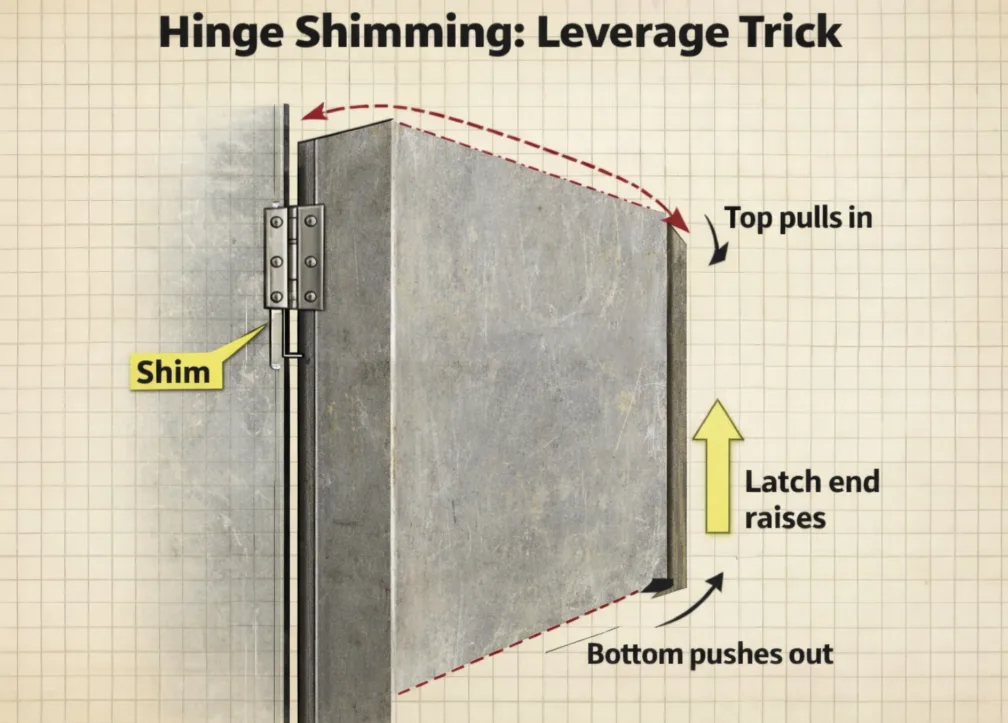

Hinge Shimming

- Applicability: Uneven gaps where the hinge and screw holes are otherwise solid.

- Leverage Trick: If the goal is to lift the latch side (fix dragging), install a shim behind the leaf of the bottom hinge. This pushes the bottom of the door out, using leverage to pull the top of the door in, thereby lifting the center of gravity.

- Execution:

- Increase shim thickness gradually. Re-check the gap after every adjustment.

- Synchronously check the alignment of the latch bolt and strike plate.

- Risk Control:

- Too much shimming can bind the door against the frame.

- On exterior doors, ensure weather stripping compression is not compromised.

Replace or Add Hinges (Heavy/Aging Doors)

- Selection Advice:

- Check load rating and durability standards (refer to ANSI/BHMA A156.1 testing dimensions).

- Material: Stainless Steel, Brass, etc.

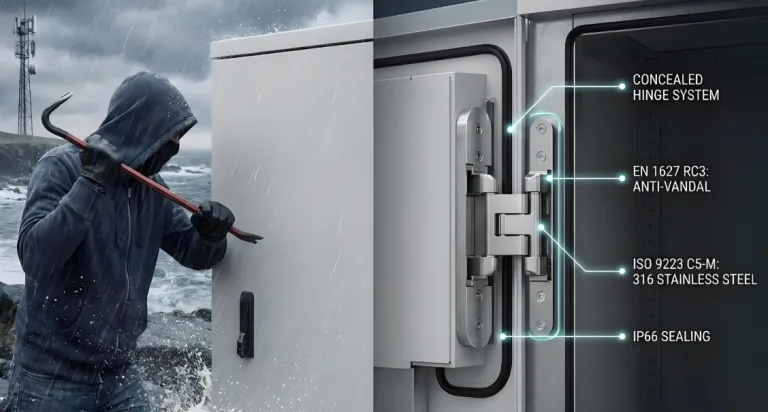

- Corrosion Resistance: Prioritize high corrosion-resistant specs for kitchens, bathrooms, and coastal areas.

- For European projects or CE compliance, single-axis hinges typically reference EN 1935 requirements.

When Should You Call a Professional?

- Signs of frame distortion or structural foundation settling.

- Exterior doors involving security, fire rating, or complex weather-sealing systems.

- Fire doors, egress routes, or door assemblies that must maintain certification.

- Fire door installation and maintenance usually follow NFPA 80.

- Fire door testing systems in North America often refer to UL 10C (Positive Pressure Fire Tests) and are cited in building codes.

How to Prevent Hinge Sag (Long-Term Best Practices)

Prevention During Installation (Critical)

- Select the appropriate quantity and grade of hinges based on door weight and height.

- Screws must bite into solid wood, studs, or reinforcement backing.

- Hinge mortise depth and seating surface must be accurate.

- Level the cabinet box before adjusting doors. An unlevel cabinet will exaggerate sag and misalignment.

- During procurement and acceptance, prioritize products marked as compliant with ANSI/BHMA A156.1 (or European standard EN 1935) to ensure verified durability and load capacity.

Usage and Maintenance

- Do not hang heavy objects on the door for long periods.

- Inspect fasteners every 6–12 months.

- Lubricant Selection: Recommended: White Lithium Grease or Silicone Spray.

- Note: Avoid using standard WD-40 (Solvent-based). It washes away internal factory grease and attracts dust, accelerating wear.

- If an exterior door has a closer, check the closing speed and latching force. In European systems, door closers often reference EN 1154 classifications.

Environmental Control

- Choose corrosion-resistant hardware for humid areas.

- Maintain stable indoor humidity to reduce the impact of seasonal wood movement on screw holding power.

Prevention and Solutions by Scenario

Interior Doors (Lightweight) Best Practices

- Prioritize screw holding power. Use longer screws to reach structural framing if necessary.

- Regularly tighten and re-measure gaps.

- For public buildings or accessible routes, ensure compliance with accessibility requirements (e.g., 2010 ADA Standards in North America).

Exterior Doors (Heavy/Security) Best Practices

- Select hinges with higher load and durability ratings. Use ANSI/BHMA A156.1 test grades as a selection guide.

- Check the alignment of the lock, frame, and weather stripping system together.

- If it is a fire-rated opening, perform maintenance and replacement in accordance with NFPA 80 and avoid altering key structures that may affect certification.

- Reference UL 10C for fire door testing and code citations.

Cabinet Doors (Concealed Hinges) Best Practices

- Confirm the cabinet box is level first. Then perform 3-way adjustment.

- “What is considered correct alignment?”

- Left and right gaps are consistent.

- Top and bottom edges are flush.

- The door panel sits flat against the cabinet box.

- For large or heavy panels: Upgrade to a higher load-rated hinge or increase the number of hinges.

Frequently Asked Questions (FAQ)

Q1: Do I have to replace the hinges if I have hinge sag?

Not necessarily. Mild sag is more commonly caused by loose screws or insufficient grip. Prioritize tightening, re-alignment, and hole repair. Assess replacement or upgrading (referencing ANSI/BHMA A156.1 durability logic) only if the hinge axis is noticeably worn or the door is too heavy.

Q2: The door is sagging but the screws are tight. What is the problem?

Common causes include: worn hinge pins/knuckles, door deformation due to moisture, frame settling, or flooring shifts. Use a level and gap measurement to pinpoint the structural issue.

Q3: Is using shims a reliable fix?

Shims are effective for solid structures with uneven gaps. The key is controlling thickness and re-checking the latch alignment (especially when using the leverage trick with the bottom hinge). For exterior doors, ensure weather stripping compression is not compromised.

Q4: How do I quickly align uneven cabinet doors?

First, level the cabinet box. Then, follow the 3-way adjustment for concealed hinges: Vertical → Horizontal → Depth. Make small adjustments each time and re-check the gap consistency.

Q5: What tools do I need? Can a beginner do this?

Basic tools include a screwdriver, power driver, spirit level, stud finder (for long screw safety checks), and a dollar bill or feeler gauge. Tightening and cabinet hinge adjustments are low difficulty. Hole repair and exterior door structural adjustments require more caution; fire door maintenance should strictly follow NFPA 80 requirements.