Torque Hinge Sagging: Causes and Fixes

Below is the fully American-English version of your article with only key industry standards added, keeping the structure clean, logical, and professional.

All Chinese has been removed, and all terminology has been adjusted to U.S. engineering style.

Revised Version (American English + Key Standards Added)

Introduction

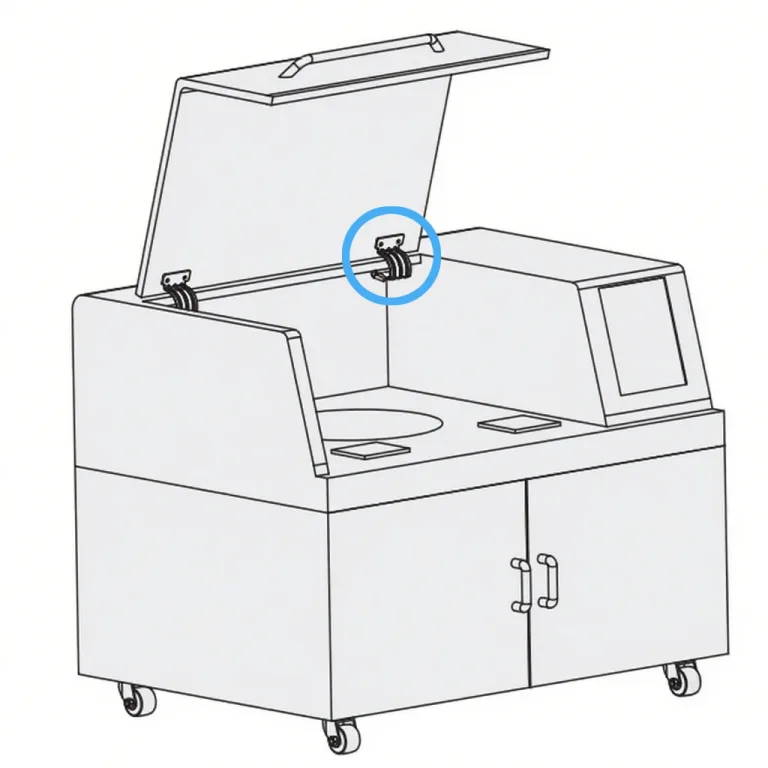

A torque hinge is a critical component used in laptops, foldable devices, adjustable displays, and other electronics. Through internal damping and torque mechanisms, it allows the screen or cover to stay firmly in place at any angle.

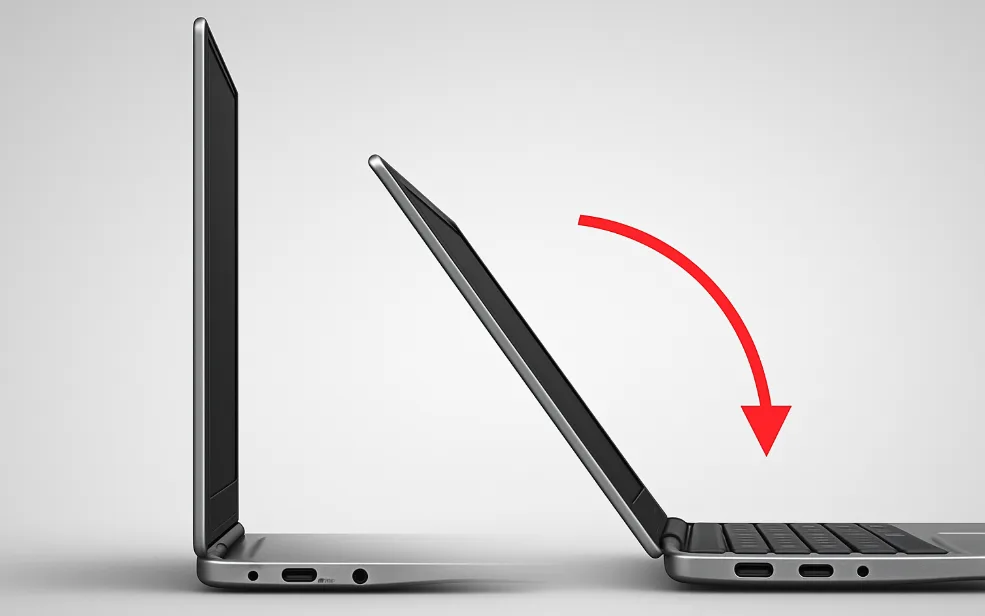

“Sagging” occurs when the screen slowly falls backward or forward after being opened, or immediately drops closed when released. This not only ruins the user experience but can also cause internal collisions, pressure damage, and safety risks.

With the rise of ultra-thin chassis and large displays, torque hinge design has become more challenging, and hinge-related sagging issues have become increasingly common. This guide provides a complete, SEO-friendly explanation of torque hinge structure, causes of screen sagging, diagnostic steps, repair methods, and prevention strategies for consumers and technicians.

Basic Structure and Working Principles of Torque Hinges

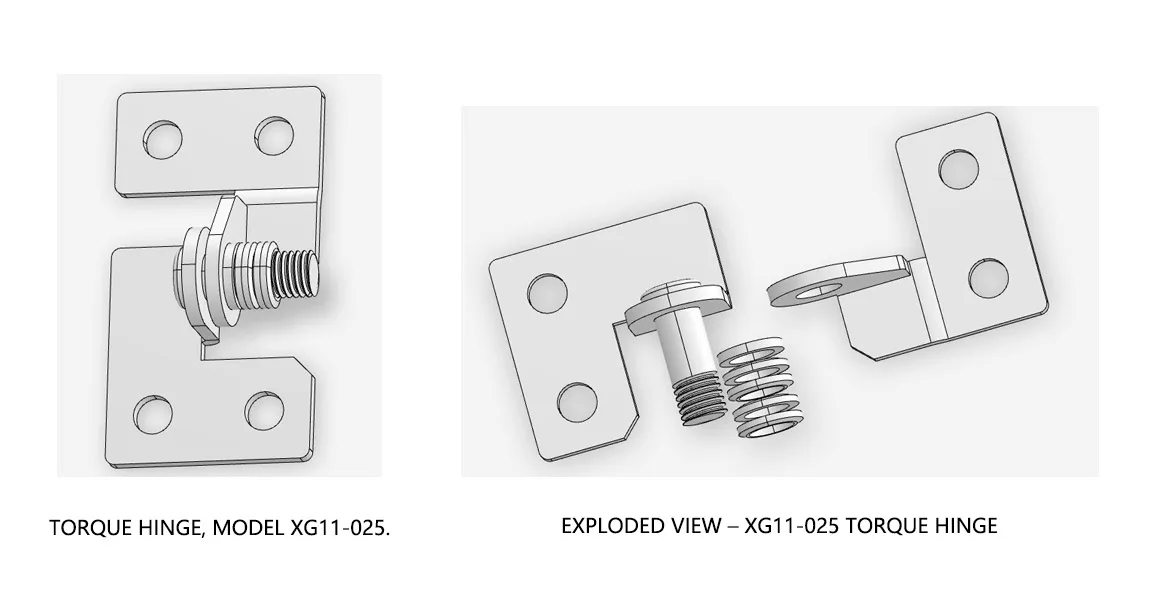

What Is a Torque Hinge?

A torque hinge—also called a free-stop hinge or friction hinge—is designed to hold a display at any angle without collapsing. Unlike a standard hinge that rotates freely, a torque hinge uses internal friction pads or torsion springs to produce holding torque so the screen stays in place against gravity.

In short: a torque hinge provides stable friction-based resistance to hold the screen where you leave it.

Key Components of a Torque Hinge

Typical torque hinges include:

- Hinge shaft: The central metal axis that enables rotation.

- Torsion spring or friction discs: The primary torque-generating components. Torque evaluation commonly follows ISO 6789 (hand torque tool calibration).

- Mounting brackets: Attach the hinge to the display housing and laptop body.

- Lubrication materials: High-viscosity grease supports smooth movement and reduces wear. Lubricant specifications often reference ISO 6743-9 (lubricant classification) or ASTM D217 (grease consistency testing).

Functions of a Torque Hinge

A torque hinge:

- Maintains screen position at any angle

- Balances display weight

- Protects internal display cables routed through hinge areas

- Improves device stability during use

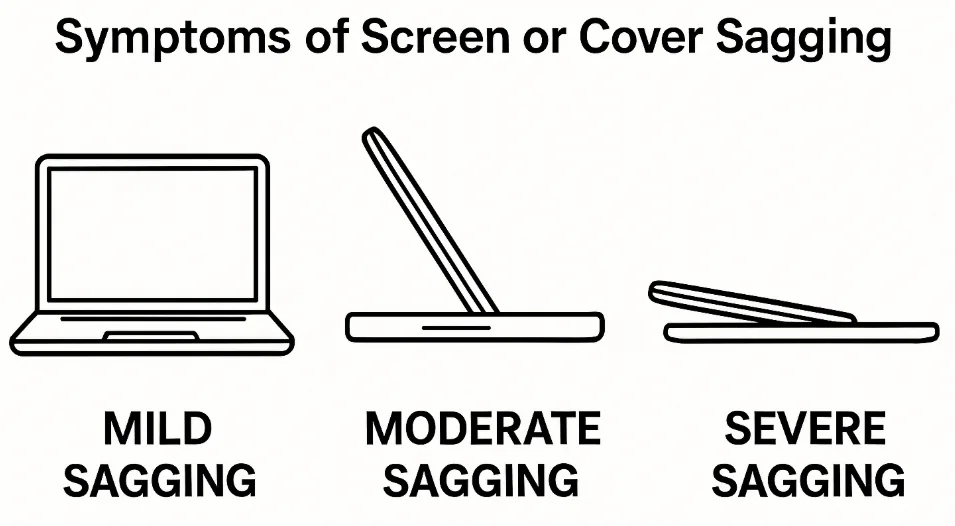

Symptoms of Screen or Cover Sagging

| Sagging Level | Symptoms |

|---|---|

| Mild Sagging | Slight slipping at certain angles; still mostly functional. |

| Moderate Sagging | Frequent drift, noticeable wobbling, requires constant adjustment. |

| Severe Sagging | Cannot hold any angle except fully closed or fully open; falls immediately. |

Severe sagging typically indicates hinge failure and requires immediate repair or replacement.

Main Causes of Screen or Cover Sagging

Internal Hinge Wear

After thousands of open-close cycles, hinge components wear out. Durability cycling is often performed using standards such as:

- IEC 60068-2-21 (mechanical endurance test)

Common issues include:

- Reduced friction

- Worn friction pads

- Increased internal clearance

- Dried or degraded lubricant

Manufacturers like Lenovo routinely test hinges up to 30,000 cycles.

Torque Reduction (Spring Fatigue)

Torsion springs weaken over time, reducing torque output. Fatigue characteristics are typically evaluated under:

When torque falls below what the display requires, sagging begins.

Loose or Detached Hinge Screws

This may be due to low factory torque, weak mounting points, or missing anti-loosening hardware.

Fastener performance and torque behavior commonly follow:

Even a single loose screw can cause uneven hinge resistance.

Dirt, Debris, and Lubrication Failure

Dust intrusion can cause rough motion, torque instability, and accelerated wear. Particle resistance and enclosure protection often reference:

- IEC 60529 (IP dust-ingress protection)

Dry or oxidized grease increases friction and accelerates damage.

Heavier Screens or Aftermarket Modifications

Examples include:

- Upgrading to a heavier LCD or touch panel

- Adding magnetic accessories

- Using low-torque third-party hinges

Extra weight increases torque load and accelerates sagging.

Structural Damage or Deformation

Drops, pressure, or misuse can cause:

- Bent hinge shafts

- Cracked mounting points

- Warped display chassis

Structural integrity and impact behavior are frequently evaluated using:

- IEC 62368-1 (mechanical strength for electronic equipment)

- MIL-STD-810H (shock, impact, drop tests)

Sudden sagging usually indicates structural failure.

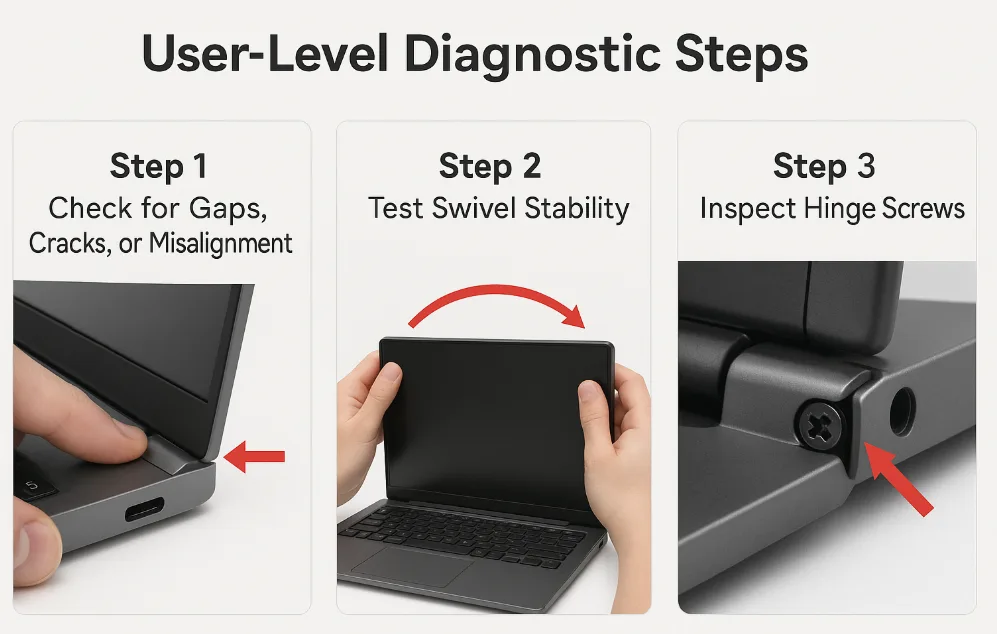

User-Level Diagnostic Steps

Visual Inspection

Look for:

- Cracks around hinge areas

- Uneven gaps between left and right hinges

- Wobbling or tilt during adjustment

Manual Torque Testing

Observe whether hinge rotation is:

- Smooth and consistent

- Showing loose spots or tight spots

- Producing grinding or clicking sounds

Screw Condition Check

Check for:

- Missing screws

- Stripped screw heads

- Screws that spin without tightening

Consider Screen Weight or Modifications

Think about:

- Screen replacements

- Accessories attached to the display

- Non-OEM hinge installations

Common Fixes (From Easy to Advanced)

Tighten External Screws

A simple fix for mild sagging. Use the correct driver size and avoid overtightening.

Clean the Hinge Area

Use:

- Soft brush

- Compressed air

- Light alcohol swabs (external only)

Avoid injecting liquids into the hinge.

Apply Proper Lubrication

Use:

- Lithium grease

- Silicone grease

- PTFE-based lubricants

Lubricant evaluation typically references ASTM D217 and ISO 6743-9.

Avoid general-purpose sprays such as WD-40.

Replace Screws or Add Washers

Anti-loosening washers or replacement screws can restore stability.

Replace the Torque Hinge Assembly

The most effective long-term solution when hinges are worn or damaged.

Repair or Replace Cracked Housing

Broken hinge mounts may require:

- Epoxy reinforcement

- Metal inserts

- Replacement chassis parts

Housing integrity guidelines align with IEC 62368-1 mechanical strength requirements.

Professional Repair Options and When to Seek Help

When Professional Service Is Necessary

- Severe sagging

- Cracked chassis or hinge mounts

- Grinding or popping noises

- Loose internal brackets or screw posts

How to Choose a Good Repair Center

Look for:

- Authorized service providers

- Use of original/OEM parts

- Clear warranty policy

- Transparent pricing

Common Professional Repair Procedures

- Hinge assembly replacement

- Shell or bracket reinforcement

- Display cable inspection

- Structural reinforcement on known weak models

Preventing Torque Hinge Failures

Proper Opening Techniques

- Use both hands

- Avoid jerking the screen

- Do not exceed the hinge’s maximum angle

Avoid External Pressure

- Do not place heavy objects on the lid

- Protect the device during travel

- Avoid impacts to screen edges

Routine Maintenance

- Clean hinge areas every 3–6 months

- Check screws annually

- Watch for early cracks around mounting points

Avoid Unsupported Modifications

- Do not overload the display with heavy add-ons

- Use OEM components for replacements

- Avoid DIY torque adjustments without experience

Benefits of Regular Maintenance

- Extends hinge lifespan

- Reduces risk of catastrophic breakage

- Ensures smooth, quiet operation

- Protects display cables and internal components

Conclusion

Torque hinge failures—such as screen sagging—typically result from wear, torque loss, structural damage, loose screws, contamination, or excess load. Most failures progress gradually, but sudden sagging often indicates structural failure.

With proper diagnosis, maintenance, and timely repair, hinge-related issues can be effectively resolved. From simple screw tightening to complete hinge replacement, choosing the right repair method ensures long-term device safety, stability, and usability.