Torque Hinges vs Gas Springs vs Springs: A Comparative Guide for Engineers

Introduction: Understanding the Role of Position Control in Modern Design

In many products and devices, position control is an essential mechanical function. Whether keeping a lid open, controlling the angle of a screen, or allowing a panel to stay at a specific position, engineers need a reliable way to manage motion and force. Without external power, maintaining an angle or ensuring smooth movement is a common requirement across multiple industries.

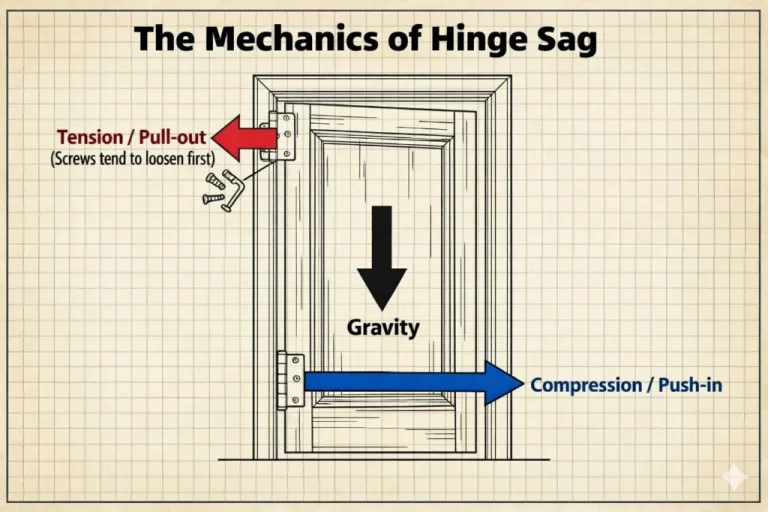

Selecting the proper solution affects product usability, safety, durability, and overall maintenance costs. If the wrong option is chosen, the following issues may occur:

- Panels may fall unexpectedly and create safety hazards

- Operation may require excessive force

- Mechanical components may wear prematurely

- Overall system stability may decrease

This article analyzes three common mechanical solutions: torque hinges, gas springs, and springs. By comparing their working principles, performance characteristics, advantages, and limitations, readers can gain a clear basis for making informed design decisions.

We begin with torque hinges.

Working Principles and Characteristics of Torque Hinges

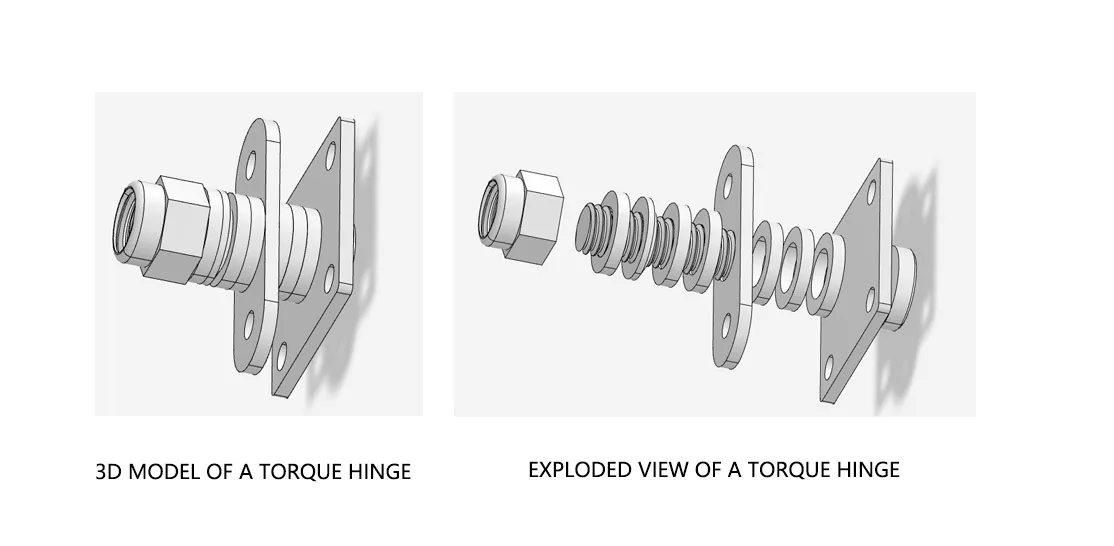

How Torque Hinges Work

A torque hinge generates resistance through internal friction components. When rotational force is applied, this resistance remains constant throughout the motion, allowing the structure to hold at any angle. Common internal components include friction plates, spring washers, and tightly fitted metal parts.

Its most notable feature is the ability to remain stable at any position without an added locking mechanism.

Main Types of Torque Hinges

Constant Torque Hinges

These maintain consistent torque across the rotation range and are often used in precision positioning applications.

Adjustable Torque Hinges

The torque level can be adjusted manually, suitable for loads that may change or require tuning during installation.

One-Way Torque Hinges

These provide higher torque in one direction and lower resistance in the opposite direction. They are used for applications that must close slowly but open easily.

Key Advantages

- Hold at any angle

- Smooth and controlled motion

- Compact size

- Predictable lifespan

- Consistent performance in typical operating temperatures

Limitations

- Do not provide lift assistance

- Torque may gradually decrease after long-term use

- Less cost-efficient for large and heavy loads

Typical Applications

- Medical displays

- Portable device stands

- Electronic screens

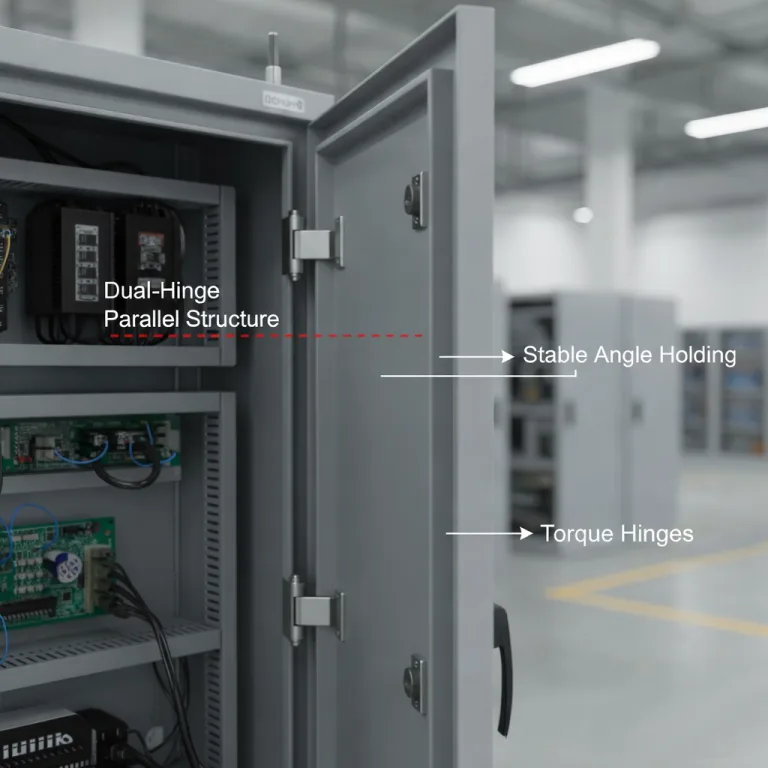

- Industrial control panels

Next, we examine gas springs, which operate very differently.

Working Principles and Characteristics of Gas Springs

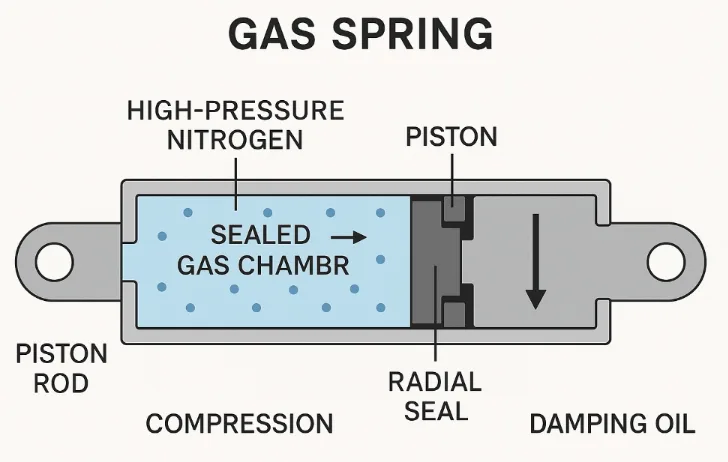

How Gas Springs Work

A gas spring consists of a sealed cylinder filled with high-pressure nitrogen gas. The pressure acting on the piston produces force. A small amount of oil provides damping to control speed. Through gas compression and expansion, the spring stores and releases energy to assist lifting or slow down closing motions.

Main Types of Gas Springs

Standard Gas Struts

The most common type, providing force during extension.

Lockable Gas Springs

These include mechanisms that allow stopping at any stroke position, often used in hospital beds or office chairs.

Traction Gas Springs

These provide pulling force rather than pushing force.

Key Advantages

- Strong lift assistance

- Controlled speed with damping

- Suitable for heavy loads

- Low operating effort

Limitations

- Force varies significantly with temperature

- Possible gas leakage

- Standard types cannot stay at intermediate positions

- Require more installation space

Typical Applications

- Vehicle trunk lids

- Adjustable furniture

- Industrial hoods and access panels

- Medical equipment supports

Now we look at springs, the simplest of the three mechanisms.

Working Principles and Characteristics of Springs

How Springs Work

A spring stores mechanical energy by elastic deformation. The force generally follows Hooke’s Law:

F = k × x

k represents the spring constant.

Types Used for Position Control

Torsion Springs

Generate torque by twisting and are used to support simple hinge actions.

Compression and Tension Springs

Provide linear pushing or pulling forces, often integrated with linkages.

Constant Force Springs

Deliver nearly constant force throughout their extension and are used where steady tension is required.

Key Advantages

- Lowest cost

- Simple and reliable

- Flexible installation options

- Little to no maintenance

- Not affected by temperature

Limitations

- No damping

- Force changes with displacement

- Cannot maintain arbitrary positions

- May require more installation space

Core Comparison: Torque Hinges vs. Gas Springs vs. Springs

Key Performance Comparison

| Feature | Torque Hinges | Gas Springs | Springs |

|---|---|---|---|

| Position Holding | Any angle | Requires locking | Balance point only |

| Lift Assistance | None | Strong | Low to moderate |

| Motion Control | Smooth | Smooth with damping | None |

| Temperature Sensitivity | Low | High | Low |

| Lifespan Stability | High | Moderate | High |

| Initial Cost | Medium | Medium to high | Low |

| Maintenance Needs | Low | Moderate | Low |

| Typical Load Range | Small to medium | Medium to large | Light to medium |

Cost Analysis: Initial Cost and Service Life

Initial Purchase Cost

- Springs: lowest

- Torque hinges: medium

- Gas springs: highest, especially lockable types

Installation Cost

- Torque hinges: simplest to install

- Gas springs: require precise mounting geometry

- Springs: may require brackets or linkages

Total Cost of Ownership (TCO)

- Gas springs may require replacement due to gas loss

- Torque hinges typically need no maintenance within rated life

- Springs are durable but may require fatigue checks over time

How to Choose: Engineer’s Decision Guide

Identify Key Requirements

Need to hold any angle?

→ Choose torque hinges

Heavy load?

→ Choose gas springs

Need damping and smooth closing?

→ Gas springs

Tight budget?

→ Springs

Large temperature variations?

→ Avoid gas springs

Limited installation space?

→ Torque hinges

Typical Application Scenarios

Medical monitors or laptop screens

→ Need angle control and stable positioning

→ Torque hinges

Automotive or industrial heavy covers

→ Need lift and damping

→ Gas springs

Simple plastic lids or lightweight mechanisms

→ Cost-sensitive

→ Springs

FAQ

1. Do torque hinges loosen over time?

They may show gradual torque reduction, but performance is predictable through testing.

Why does gas spring force change with temperature?

Gas pressure is proportional to temperature, increasing or decreasing force accordingly.

Can springs provide position holding?

Not unless combined with damping or locking mechanisms.

Can a leaking gas spring be repaired?

Sealed gas springs generally cannot be repaired and must be replaced.

What environments are ideal for torque hinges?

They perform well in applications with temperature fluctuations, limited space, and high precision requirements.

Conclusion: Making the Best Decision for Your Design

Torque hinges, gas springs, and springs each have distinct strengths. The best option depends on load requirements, available space, temperature conditions, user experience expectations, and budget.

- Torque hinges: best for position holding

- Gas springs: best for lift assistance and controlled motion

- Springs: best for simple, cost-sensitive designs

With the analysis provided in this article, you should now have a clear foundation for selecting the most suitable solution for your application.