Why Do Torque Hinges Require Matched Pairs? (Technical Guide)

Why Do Torque Hinges Often Require Matched Pairs?

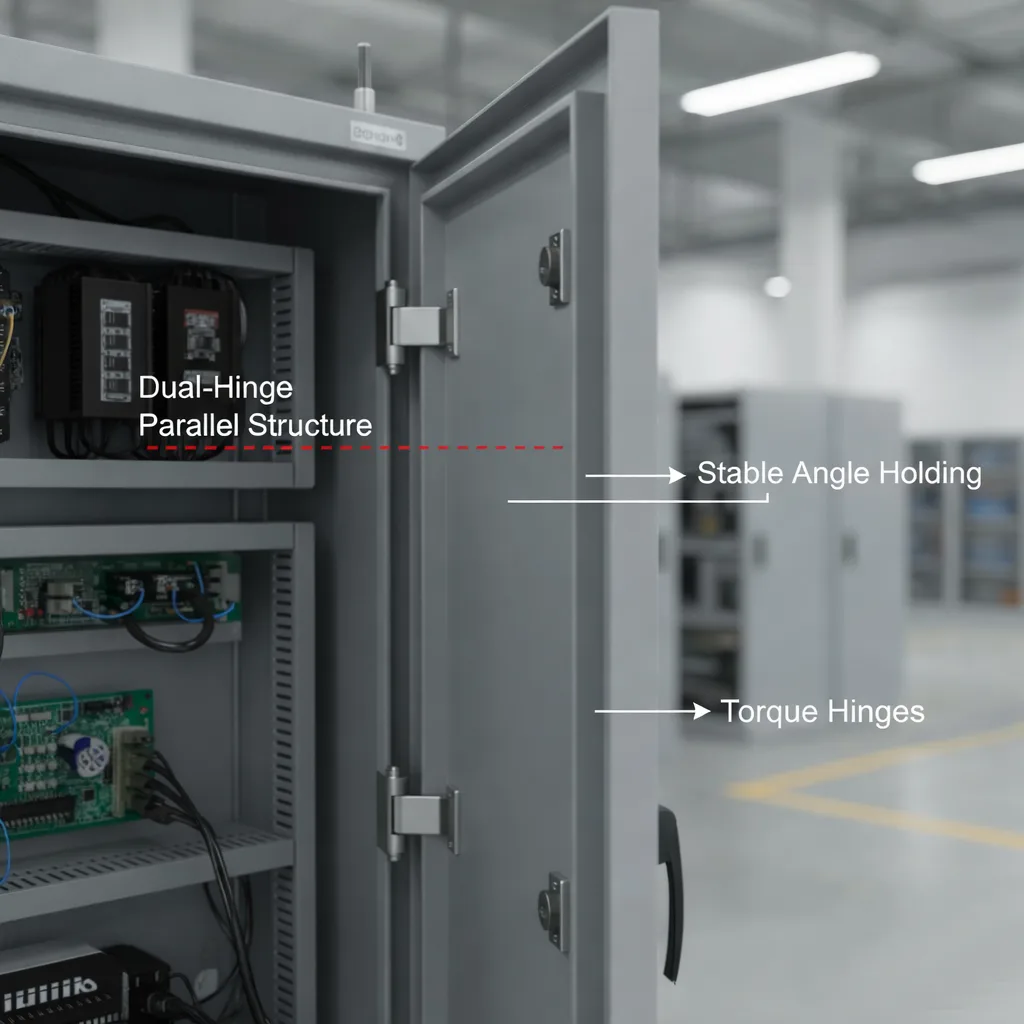

Torque hinges are widely used in monitor stands, equipment covers, cabinet doors, hatches, and medical device panels. Across these products, engineering teams typically prioritize three performance outcomes: (1) stable angle holding, (2) consistent operating feel, and (3) reliable performance after long-term cycling.

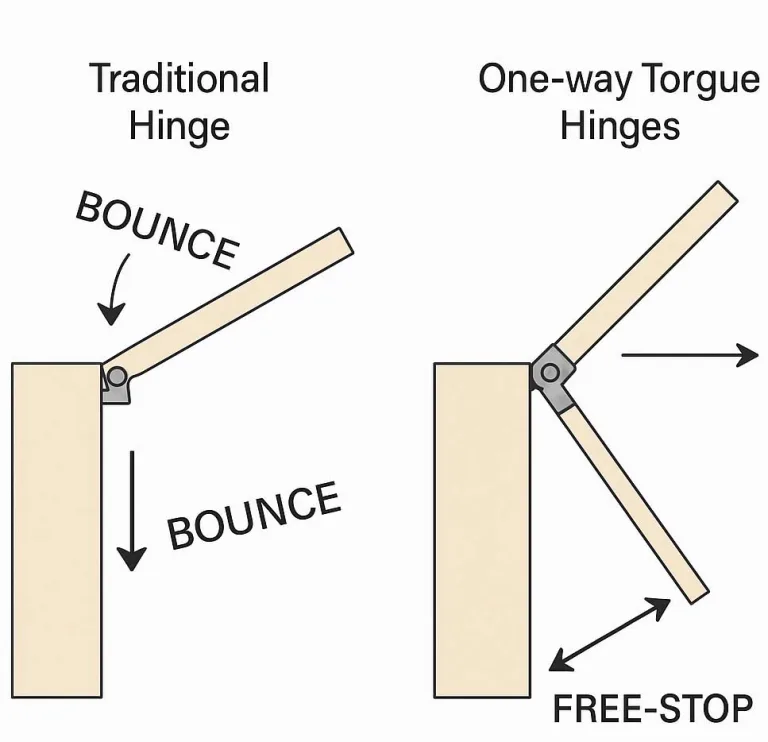

In a dual-hinge parallel structure, the left and right hinges resist motion and share the load simultaneously. If the two hinges differ meaningfully in torque, breakaway friction, or hysteresis behavior, the system becomes prone to skewing, binding, noise, and accelerated single-side wear.

To mitigate these risks, many suppliers offer “matched pairs”. This process involves factory screening, grouping, and identifying two hinges—often high-performance Constant Torque Hinges—that behave closely enough to reduce left-right variability, enabling repeatable verification and standardized incoming inspection.

Procurement Quick Guide (What to Buy and How to Accept)

When Matched Pairs Are Strongly Recommended

Specify matched pairs when your project utilizes Friction Hinges in any of the following scenarios:

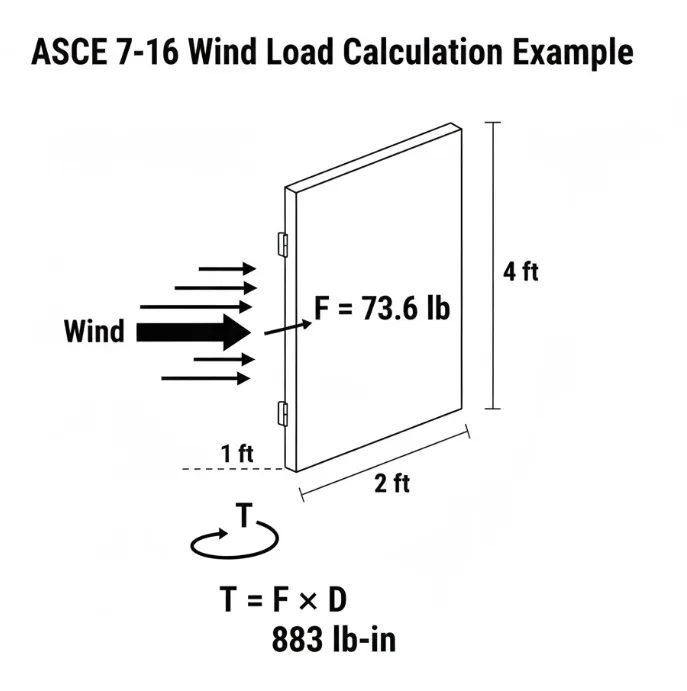

- Wide panels / long lever arm: the center of gravity is far from the hinge axis, making the system sensitive to left-right differences.

- Strong “hold” requirement: the panel must hold stable angles without droop, spring-back, or uneven feel—a common challenge for standard Positioning Hinges.

- Cosmetic and noise sensitivity: visible gaps, rubbing marks, squeak/click noise, or premium tactile feel are key quality metrics.

- Plastic / thin sheet metal structures: holes can elongate and parts creep under asymmetric loading, increasing skew risk over time.

Purchase Spec: 5 Lines You Can Copy into PO / Spec

Use the following items as a practical, buyer-friendly matched-pair purchase clause. These lines also help engineers validate and troubleshoot faster.

- Matched pair delivery & identification: Hinges must be delivered as matched pairs. Each pair must carry a Pair ID on label/packaging (and on part if feasible) to prevent mix-up.

- Single-hinge torque range (T): Provide torque range T = xx–xx N·m per hinge, including test angle, test speed, and test temperature used by the supplier.

- Pair consistency (ΔT): For each matched pair, the left-right torque difference must satisfy ΔT ≤ xx N·m (or ≤ x%). Define the angle(s) where ΔT is evaluated (e.g., 30°/60°/90°).

- Direction requirement: Supplier must provide the correct LH/RH or CW/CCW combination per drawing and clearly mark direction to prevent assembly errors.

- Traceability / factory record: Supplier must provide traceability by Pair ID (batch code, inspection record, or test data summary). At minimum: initial torque data at the specified angle points; if required, add life-stage data after cycling.

Incoming Inspection: 3 Simple Checks

- Check Pair ID & direction markings: confirm pair integrity and LH/RH (or CW/CCW) are correct before line loading.

- Quick torque consistency sampling: sample n pairs, measure at fixed angles (commonly 30°/60°/90°) under the same conditions, and verify ΔT requirement.

- Assembly feel & skew sanity check: install on a representative fixture/panel and perform a short open-close trial to confirm no abnormal binding, noise, or visible skew.

Defining Matched Pair Torque Hinges

A shared model number does not guarantee a matched pair. Even within high-quality Constant Torque Hinges, torque distribution can vary due to material batch differences, friction couple variation, assembly preload, and lubrication state. A “matched pair” typically means the supplier applies stricter controls and provides identification so the two hinges behave similarly in the real assembly.

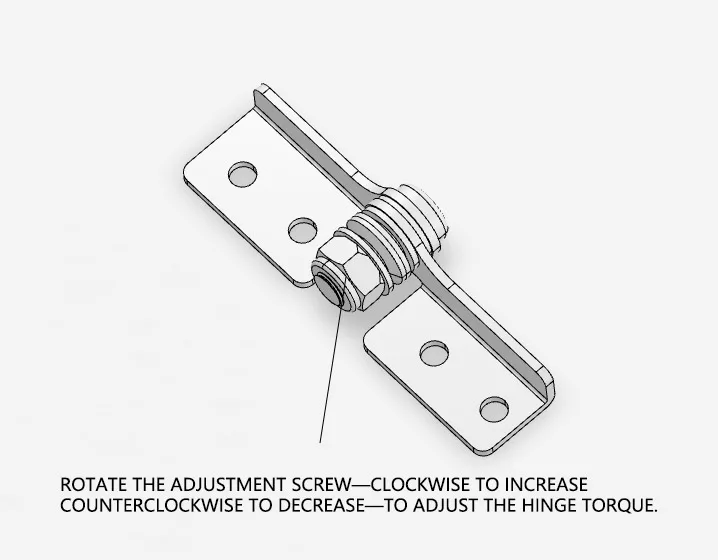

In practice, a matched pair specification usually includes:

- Closer torque window: both hinges fall within a tighter torque band to support system torque budgeting.

- Consistent direction: bidirectional or unidirectional behavior aligns with the intended LH/RH or CW/CCW installation orientation.

- Similar friction feel: breakaway and running torque are closer; hysteresis (feel difference between opening and closing) is more consistent.

- Factory grouping & traceability: Pair IDs, labels, or serial pairing enable incoming inspection and traceable quality management.

Common supplier pairing methods:

- Batch binning: screen hinges into a target torque interval and pair within that tighter window.

- Left/Right mirror pairing (LH/RH): ensure the torque direction remains correct after installation orientation is reversed.

- Serial / record binding: Pair ID or serial pairing links factory test records to the delivered pair for traceability.

Core Reasons to Specify Matched Pair Torque Hinges

Tolerance Stack-up Doesn’t “Average Out” in Parallel

Torque hinges generate resistance through friction interfaces and preload structures. Manufacturing tolerances, friction material variation, and assembly preload differences create torque spread. A single hinge may feel acceptable on its own, but in a dual-hinge system the user feels the combined resistance and the left-right difference. Instead of averaging out, mismatches in Positioning Hinges show up as uneven feel, skew tendency, and inconsistent holding angles.

Practical spec wording tip: state the single-hinge torque range (N·m) and clearly define test angle, speed, and temperature. Then add a matched-pair consistency requirement (ΔT window) and require the supplier to describe pairing and identification.

Unbalanced Torque Increases Offset Loading and Structural Risk

The two hinges share door weight and operating moment. If one hinge produces higher torque or higher friction, it tends to take more of the moment and dissipate more energy. That imbalance transfers risk to structural parts and fasteners, especially on plastic or thin sheet metal. When using Constant Torque Hinges on flexible housings, increasing local stiffness at hinge mounts and controlling coaxial alignment reduces sensitivity.

Design note for ID/ME: torque mismatch is amplified when the panel is wide, when hinge spacing is large, or when the housing is flexible. Typical failure paths include: mounting holes elongating, brackets skewing under stress, and cosmetic gaps widening due to creep.

Reducing Racking and Warping Reduces Noise and Rub Marks

When left and right resistance differs, the panel experiences slight twisting (racking). Racking makes edges contact the housing earlier, creating corner-first interference, uneven gaps, localized rubbing, and noise (squeak/click/scratch). Matched pairs reduce the chance that the hinge set itself becomes the main driver of racking, making mechanical clearances and cosmetic tuning more predictable.

Matched Pairs Slow the Growth of Left-Right Difference Over Life

The higher-torque side usually dissipates more energy and can wear faster, which increases torque drift and enlarges the left-right difference over cycles. For products requiring stable holding angles and consistent feel, life verification is more actionable when recorded in stages:

- Initial: torque vs. angle (or fixed angle point data).

- After cycling: repeat under the same conditions.

- Trend: track how ΔT changes with cycles (this is often more important than absolute torque shift).

For teams that need a structured cycle/wear/friction/strength verification framework, ANSI/BHMA A156.1 can be used as a reference baseline for how to stage and record hinge performance.

Matched Pairs Improve Production Yield and Reduce Line “Feel Tuning”

In mass production, the pain usually comes from batch variation and on-line feel adjustments. Matched pair delivery means the supplier has already screened, grouped, and marked the hinges. This reduces reliance on subjective operator feel and helps standardize assembly, spot checks, and rework decisions.

If tightening consistency influences hinge behavior (especially where mounting stack-up affects alignment or preload), implement torque tool control and calibration within the production process.

Common Symptoms of Mismatched Torque Hinges

Mismatched pairs often present as:

- Sudden change in resistance at certain angles (one side “catches” or “lets go”).

- Poor holding stability (droop or spring-back).

- Uneven left-right gaps or visible panel skew.

- Noise, rubbing marks, or edge scratching.

- Feel degrades over time and the left-right difference grows with use.

These symptoms can have multiple causes (structure rigidity, alignment, clearances, lubrication, contamination). The value of matched pairs is that they first converge the “left-right torque difference” variable, making root-cause analysis more controllable.

Applications That Benefit Most from Matched Pairs

High-Benefit Applications

- Industrial equipment covers and cabinet doors.

- Medical equipment panels and display flip covers where Constant Torque Hinges ensure smooth operation.

- Self-service terminals, POS systems, and monitor stands.

- Automotive / outdoor equipment where vibration, temperature swing, and humidity increase variability sensitivity.

For projects with environment sensitivity, define environmental verification methods and severity levels in the project specification. The IEC 60068 family can be referenced as a method library for temperature, damp heat, vibration, and shock test planning. For heavy-duty vehicle environment definition (temperature/vibration context), SAE J1455 is often used as a reference baseline for duty environment expression.

Applications That May Only Need Evaluation (Not Always Matched Pairs)

- Small, light-load covers.

- Single-point hinge structures (only one torque hinge).

- Structures where guides, dampers, or gas springs share the load and stabilize motion.

If the product still demands consistent feel or stable holding angles, consider at least same-batch grouping, or adopt matched pair delivery to reduce variability risk.

Quick Decision Guide: Matched Pairs vs. Standard Units

Matched pairs are typically the better default when:

- The panel is wide and the center of gravity is far from the hinge axis.

- Stable holding at multiple angles and consistent feel are core UX requirements.

- Plastic / thin sheet metal parts make the assembly sensitive to creep and hole elongation.

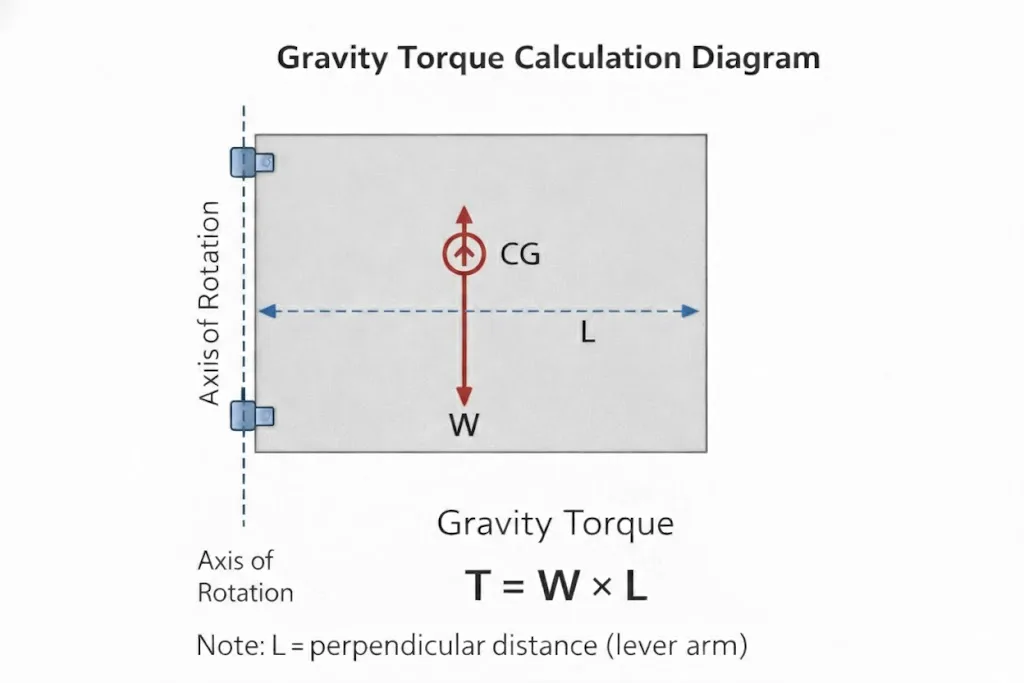

For torque budgeting, use system-level thinking:

- Gravity torque ≈ Weight × Distance from CG to pivot axis.

- System available torque ≈ Torque of left hinge + torque of right hinge (when installed symmetrically).

Always verify margins using representative samples and a clearly defined test condition set (angle, speed, temperature). This avoids lab-to-lab and supplier-to-supplier data mismatches.

How to Write a Spec That Works for Both Procurement and Engineering

A robust matched-pair torque hinge specification is easy to purchase, easy to inspect, and easy to validate. Organize your document around four blocks: pairing & traceability, torque & direction, test conditions & records, and life/environment/finish.

Pairing and Traceability

- State whether matched pairs are required.

- Define Pair ID / label rules and packaging separation requirements.

- Require the supplier to disclose the pairing method (binning, LH/RH mirroring, or serial/record pairing).

Torque Specifications and Direction

- Single-hinge torque range (N·m) and evaluation angle(s).

- Pair consistency index (ΔT limit or matching window) and evaluation method.

- Unidirectional vs. bidirectional torque; clarify CW/CCW or LH/RH orientation and marking requirements.

Test Conditions and Recording Requirements

- Angle range / angle points.

- Test speed and temperature (and any lubrication state requirement if relevant).

- Record requirements: initial torque curve or point data; add post-life stage records when needed.

Life, Environment, Protection, and Finish

- Cycle life: define target cycles and failure criteria; use a consistent framework for cycle/wear/friction/strength staging (ANSI/BHMA A156.1 can be referenced as a framework when appropriate).

- Environment: select and document environmental tests and severity (IEC 60068 family as a method library).

- Ingress protection (if required): specify target IP rating and verification method (IEC 60529).

- Corrosion / finish: define corrosion class and verification method; clarify exposure duration and pass/fail judgment in your spec rather than relying only on generic salt spray language.

Sample Verification (Sample → Cycle → Retest → Record)

To keep verification reproducible across suppliers and labs, structure testing as:

- Test on real assemblies: use real covers or equivalent fixtures with representative stiffness and hinge spacing.

- Fixed-angle evaluation: record feel and holding at defined points (e.g., 0°, 30°, 60°, 90°).

- Retest after cycles: focus on torque drift and ΔT growth, not only absolute torque change.

- Record structural indicators: hole deviation, gap change, and panel rigidity checks help avoid misattributing structural issues to hinge performance.

Assembly and Process Control Points

- Direction consistency: execute LH/RH and CW/CCW installation per drawings and markings.

- Holes and axes: avoid forced assembly; poor coaxiality can create internal stress and fake “hinge mismatch” symptoms.

- Preload / fastening consistency: standardize tightening torque and sequence; retain tool control records when required.

- Spacing and rigidity: larger hinge spacing increases sensitivity to ΔT; evaluate spacing together with panel stiffness and cosmetic gap strategy.

Torque Hinge FAQ

Q1: What is the key difference between a matched pair and two units of the same model?

Matched pairs focus on pair consistency and traceability. Same-model hinges can still have a wider torque/friction distribution. Matched pairs typically include screening, grouping, identification, and (often) better record linkage.

Q2: Can assembly adjustments “fix” mismatched hinges?

Short-term feel tuning may reduce obvious differences, but it can introduce structural pre-stress and create long-term risks. Long-term consistency is best achieved by converging the pairing window in the specification and verifying it with a repeatable method.

Q3: Do we have to specify CW/CCW or LH/RH?

If opening direction or torque direction affects holding behavior, you should clarify direction and require clear markings and traceability to prevent assembly mistakes.

Q4: Why do matched pairs cost more?

The premium typically comes from factory screening, grouping, identification, and traceability management. In return, you usually get better production yield, fewer on-line adjustments, and a more controllable acceptance path.

Q5: How should we write corrosion resistance requirements?

Define a target corrosion grade/class and bind it to a chosen verification method, then explicitly state exposure duration and pass/fail rules in your specification. Avoid leaving “interpretation space” that later turns into supplier disputes.

Conclusion

Matched pair torque hinges are specified to control five real-world risks: (1) reduce left-right torque variability that becomes obvious in parallel structures, (2) improve load balance and reduce structural deformation risk, (3) reduce racking-driven noise and cosmetic rubbing, (4) slow the growth of torque drift and left-right difference over life, and (5) improve assembly consistency and mass production yield. The most effective execution strategy is to write a buyer-friendly, testable specification: require paired identification, define single-hinge torque and pair ΔT limits under clearly stated test conditions, and stage verification with recorded data before and after cycling.

Appendix: Reference Standards (Grouped by Purpose)

Note: Keep the main body focused on “what to buy / how to accept / how to validate.” Use this appendix as the engineering library when writing project specs and test plans.

- Cycle / wear / friction / strength framework: ANSI/BHMA A156.1

- Environmental methods (temperature, damp heat, vibration, shock): IEC 60068 series

- Ingress protection (dust & water): IEC 60529 (IP Code)

- Corrosion classification / building hardware logic: EN 1670

- Salt spray method references: ISO 9227; ASTM B117

- Furniture/cabinet hinge durability references (vertical axis contexts): EN 15570

- Single-axis hinge classification & durability context: EN 1935

- Torque tool calibration (if fastening control is a requirement): ISO 6789-2

- Heavy-duty vehicle environmental context definition: SAE J1455

- Quality / risk / compliance language (as applicable to supplier programs): ISO 9001:2015; ISO 12100:2010; RoHS (2011/65/EU); REACH (EC) No 1907/2006; IEC 60601-1 (medical device system context)