Is It a Quality Issue? Why Torque Hinges Lose Strength and How to Prevent It

For any high-end equipment, the initial ‘feel’ of the lid or screen is a signature of quality. Torque hinges (or friction hinges) are the hidden components responsible for this premium, precise positioning. But the real challenge isn’t how they feel on day one—it’s how they perform on day 500. As devices move from the showroom to the field, engineers frequently encounter a frustrating reality: the once-stiff resistance fades, displays start to droop, and that reliable tactile feedback turns into a loose, unresponsive slide.

This phenomenon is often categorized immediately as a “product quality defect.” However, within the scope of engineering and Tribology, this change is frequently a predictable, gradual attenuation process governed by physical laws. Unless there is a fracture or functional failure, most torque reduction stems from the interaction between material properties and environmental factors.

This article systematically explains the technical reasons why torque hinges “lose tension” over time from three dimensions: engineering structure, materials science, and actual operating conditions. It also provides professional advice on selection and verification based on relevant testing standards (e.g., ASTM, EN, BIFMA).

What is Torque Decay?

The Engineering Definition

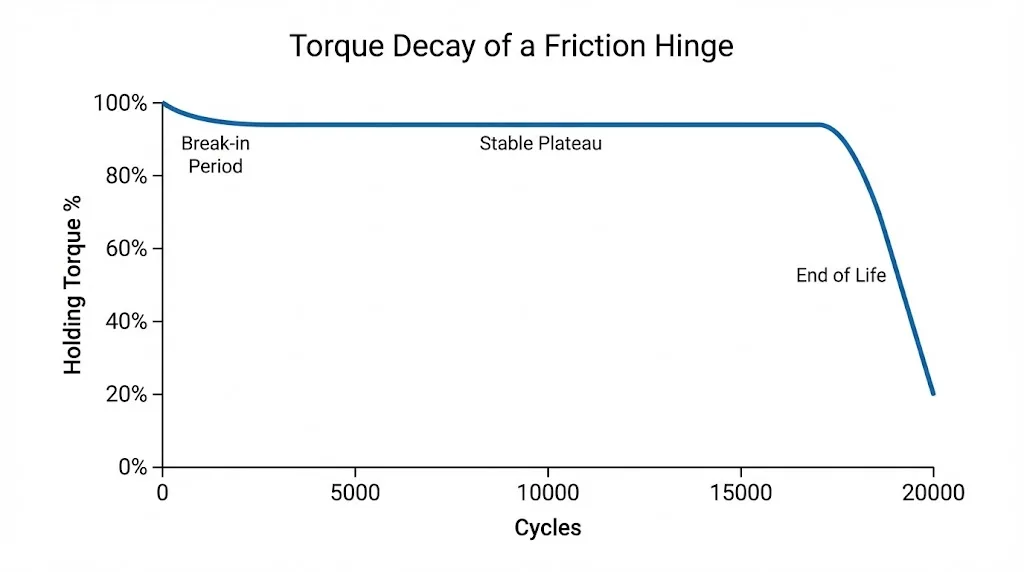

In engineering applications, Torque Decay refers to the trend where the output holding torque of a hinge gradually decreases after undergoing a specific number of open/close cycles or long-term static loading. It is a dynamic performance degradation parameter.

Specific technical manifestations usually include changes in the following data metrics:

- Reduction in Static Holding Capability: A door panel that originally stayed at any angle begins to slide slowly (Creep) under gravity.

- Angle Drift (Backlash/Spring-back): After stopping operation, the hinge cannot lock in the predetermined position, resulting in a few degrees of rebound or looseness.

- Weakened Damping Feel: The differential between Breakaway Torque and Dynamic Torque changes, causing the user to feel a significant reduction in the force required for operation.

Distinguishing Decay from Structural Failure

Differentiating between “performance attenuation” and “structural failure” is critical for failure analysis:

- Torque Decay: This is a continuous, progressive process. For example, a hinge rated at 2.0 N·m drops to 1.6 N·m after 10,000 cycles (a 20% decay). This typically falls within the allowable tolerance of the design.

- Structural Failure: Refers to component fracture, seizure, shaft deformation, or the shattering of internal parts.

Most industrial standards (such as EN 15570 – Strength and durability of furniture hardware) acknowledge that torque variation is a normal physical phenomenon. Typically, qualified industrial-grade product specifications will state that within the rated life cycle, the torque variation range is controlled between ±10% to ±20% of the initial value.

How Torque Hinges Generate and Maintain Torque

Internal Structure of Typical Hinges

To understand the decay mechanism, one must first deconstruct the physical structure generating the torque. While proprietary designs vary by brand, most friction hinges contain the following core elements:

Shaft: Usually made of hardened steel or stainless steel, serving as the core load-bearing component.

Friction Elements (The Pair): Components that wrap around or contact the shaft, including wrapped clips, friction discs, or cone friction assemblies.

Pre-load Components: Parts that provide continuous pressure, such as wave springs, Belleville washers, or the elastic metal clip itself.

Lubrication or Damping Medium: High-viscosity damping grease filled between contact surfaces to smooth the tactile feel and reduce wear.

Basic Physics of Torque Formation

Torque generation follows classical friction mechanics. Engineering designs generate Normal Force via axial or radial pre-load, and the friction elements convert this pressure into rotational resistance.

The simplified calculation formula is:

T = μ × F × r × N

Where:

- T = Output Torque

- μ = Friction Coefficient (dependent on materials and lubrication)

- F = Pre-load (Normal Force)

- r = Friction Action Radius

- N = Number of Effective Friction Surfaces

*In Plain English:

- μ (Friction): Represents the quality of the grease. Cheap grease flows away like water when hot, causing the hinge to lose grip instantly.

- F (Pre-load): Represents the spring strength. If the spring steel is poor quality, it acts like a stretched rubber band that won’t snap back, resulting in a loose lid.*

As seen, the torque magnitude is not constant; it relies entirely on the long-term stability of μ (friction state) and F (pre-load). Any factor causing these two parameters to drop will directly lead to torque decay.

6 Engineering Causes for Torque Loss (Core Analysis)

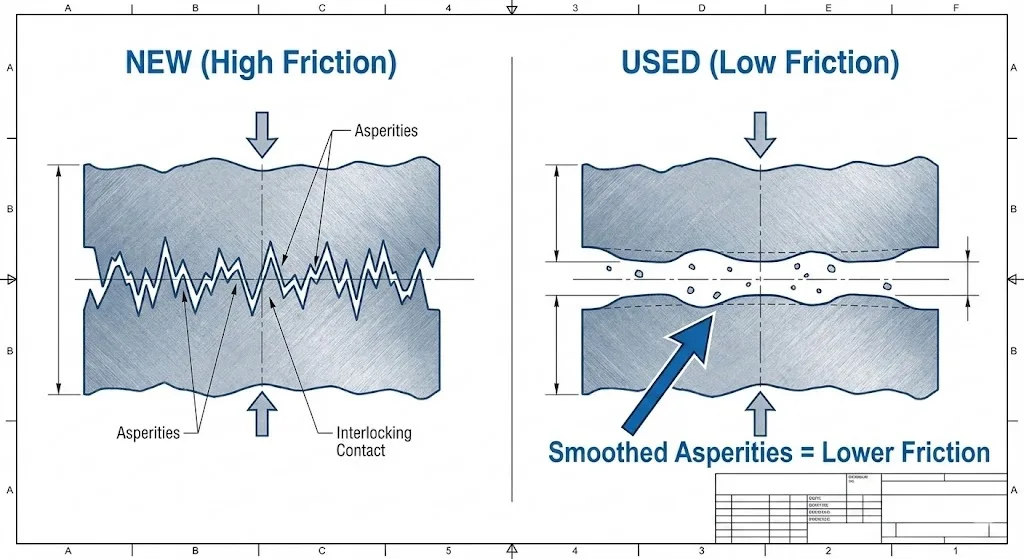

Wear of Friction Materials

As asperities are worn down, mechanical interlocking is reduced, resulting in lower friction coefficient and a measurable decrease in hinge holding torque.

This is the most direct physical cause of torque reduction.

- Microscopic Surface Morphology Change: At the microscopic level, the contact surfaces of the shaft and friction clips are not perfectly smooth. During repeated rotational motion, the asperities (micro-projections) on the contact surfaces are gradually smoothed out.

- Reduction in Effective Interference: For hinges designed with an Interference Fit, wear means the interference volume between the shaft and the friction sleeve decreases.

- Data Result: As material is removed, the Normal Force ($F$) in the formula above decreases due to geometric dimensional changes, directly lowering the output torque. This explains why most hinges experience the fastest torque drop during the “break-in period” (the first 500-1,000 cycles), after which they tend to stabilize.

Aging or Migration of Lubrication Media

Grease in torque hinges serves not only as a lubricant but also provides Viscous Damping.

- Shear Thinning: High-performance damping greases are non-Newtonian fluids. Under high-frequency operation, the viscosity of the grease decreases.

- Grease Migration: Under long-term heat exposure or centrifugal force, grease may be squeezed out of the friction interface and migrate to non-working areas.

- Transition of Friction Properties: When grease is lost, the friction pair may transition from a “mixed lubrication” state to “boundary lubrication” or even “dry friction.” While dry friction coefficients are higher, they lead to drastically accelerated wear, eventually causing increased clearance and torque failure.

Pre-load Release or Elastic Element Fatigue

Torque maintenance is highly dependent on the constant pressure provided by pre-load elements.

- Stress Relaxation: Metal springs or Belleville washers subjected to high stress compression for long periods will experience stress relaxation. Even if the deformation amount remains unchanged, their internal restoring force decreases over time.

- Creep: If the hinge structure includes engineering plastics (such as Polyacetal POM or Nylon PA66), the plastic will undergo “Cold Flow” or Creep under sustained load, leading to irreversible changes in mating dimensions.

- Result: The axial force ($F$) decays naturally over time, causing a synchronous reduction in torque.

Assembly Errors Causing Uneven Loading

Manufacturing tolerances and assembly precision directly affect wear rates.

- Shaft Misalignment: If the axes of two hinges on a door panel are not collinear, rotation induces additional radial loads on the internal bearings.

- Localized Point Loading: This misalignment causes the friction pair to endure extreme pressure in localized areas (Point Loading). The wear rate in this zone will be significantly higher than the design expectation.

- Accelerated Failure: Once localized wear forms a gap, the overall pre-load is released rapidly, causing the hinge to loosen well before reaching its design life.

Operating Conditions Exceeding Design Assumptions

Lab tests are typically conducted in ideal environments, whereas actual operating conditions are often harsher.

- Dynamic Shock: The action of a user slamming a door, or vibration during equipment transport, generates instantaneous Shock Loads. This can cause micro-displacement or plastic deformation of the friction clips.

- Heat Accumulation: High-frequency, rapid operation generates frictional heat. If this heat cannot dissipate timely, it leads to thermal expansion of friction materials or carbonization of the grease, altering the friction coefficient.

Environmental Factors Affecting Material Performance

Environmental stress is a critical variable causing performance deviation that is often overlooked.

- Temperature Fluctuations: Different materials have different Coefficients of Thermal Expansion (CTE). For instance, a steel shaft and a plastic housing expand at different rates. High temperatures may increase the gap (lowering torque), while low temperatures may cause seizing (increasing torque).

- Chemical Erosion: In medical or food processing environments, frequently used disinfectants or cleaning agents may penetrate the hinge, degrading the grease or corroding metal springs, leading to pre-load failure.

Why Hinges Droop Despite Correct Theoretical Calculations

Limitations of Static Torque Calculation

Engineers typically use the following formula for selection:

Torque = Length (L) × Weight (W) × 0.5 × Safety Factor

This calculation has limitations:

- Ignoring Center of Gravity (CG) Shifts: It is usually based on a static CG position. However, during equipment motion, cable drag forces or fluid movement shift the actual load.

- Confusing Dynamic vs. Static Torque: Most hinges have a higher “Breakaway Torque” (to start moving) than “Dynamic Torque” (while moving). Equipment requires enough force not just to “hold” still, but to move smoothly. If the holding torque is barely passing, slight vibrations will cause the panel to droop.

The Stack-up Effect of Manufacturing Tolerances and Decay

This is the classic engineering “Worst-case Scenario”:

Assume a hinge has a nominal torque of 1.0 N·m with a manufacturing tolerance of ±20%.

The received product happens to be at the lower tolerance limit: 0.8 N·m.

After one year of use, the product undergoes 20% normal engineering decay, dropping the torque to 0.64 N·m.

Conclusion: The actual torque (0.64 N·m) is now far below the theoretical design requirement of 1.0 N·m, resulting in severe drooping issues.

Which Applications Are Most Prone to “Loosening”?

High-Frequency Operation Equipment

- Industrial Control Panels / HMIs: Operated hundreds of times daily on production lines.

- Medical Cart Monitors: Frequently adjusted by nurses and doctors during rounds.

- Laboratory Analysis Instrument Covers: High-frequency sample loading/unloading operations.

In these scenarios, cumulative wear accumulates rapidly, requiring higher-grade wear-resistant materials.

Light Load but Off-Center Structures

- Ultra-thin Flat Panel Displays: Light weight, but long lever arms.

- Doors with Added Modules: If a door has cable harnesses, sensors, or gas springs attached, these components create indeterminate reaction forces, rendering the originally calculated torque margin insufficient.

Can Torque Decay Be Completely Avoided?

Realistic Engineering Conclusion

From a physics perspective, where there is friction, there is wear; where there is stress, there is relaxation. Therefore, Zero Decay is impossible.

The engineering goal is not to eliminate decay but to control the rate of decay so that it remains within the functional range throughout the product’s effective Life Cycle.

Reasonable Engineering Expectation Management

- Define End of Life (EOL): Specifications should define what constitutes EOL. For example: “After 20,000 cycles, torque drop shall not exceed 20% of the initial value.”

- Safety Factor: It is recommended to reserve a 30% – 50% torque margin during the design phase to offset future performance attenuation.

Design Strategies to Mitigate Torque Decay

Structure and Material Control Strategies

- Select Correct Friction Pairs: Hardened steel on hardened steel, or steel on engineering plastic, is generally more wear-resistant than soft metal combinations.

- Increase Friction Area: Where space permits, choose multi-fin or multi-disc friction structures instead of single-point contact designs to disperse surface pressure.

- Use Compensation Structures: Select designs with adjustable nuts or automatic compensation springs that can mechanically restore partial pre-load after wear occurs.

Need help choosing between Stainless Steel 304 and 316 for your specific application? Refer to our detailed guide: [Ultimate Guide to Torque Hinge Selection & Material Comparison]

Testing and Verification Recommendations

Do not rely solely on supplier datasheets. It is recommended to perform verification compliant with the following standards:

- Life Cycle Testing: Refer to SEFA 8M-2016 (Laboratory Grade Metal Casework standards) or the hinge durability sections in ANSI/BIFMA X5.5.

- Simulate Actual Conditions: Test with real door weights and CG distributions, not just by rotating the hinge shaft in a chuck.

- Environmental Aging: Conduct thermal cycling tests to verify the impact of thermal expansion/contraction on torque retention.

FAQ

Q1: Is a torque hinge getting loose always a quality issue?

A: Not necessarily. In most cases, this is a normal physical phenomenon caused by material wear and stress relaxation. It is only considered a quality anomaly if the torque drops drastically within a very short period (e.g., a few dozen operations) or causes total functional loss.

Q2: When does torque decay typically occur?

A: It usually follows a “Bathtub Curve.” Torque drops noticeably during the initial break-in period (first 5% of life), then enters a long stable period, and finally accelerates in decline at the end of its life. The specific timing depends on load and frequency.

Q3: Are adjustable torque hinges more prone to loosening?

A: If the adjustment mechanism is properly designed (e.g., equipped with lock nuts or thread-locking adhesive), they are not more prone to loosening than fixed hinges. However, in high-vibration environments, unlocked adjustment screws do pose a risk of backing out.

Q4: Can torque be restored by re-adjusting the hinge?

A: If the hinge has an adjustment screw and the decay is due to pre-load relaxation, torque can often be restored by tightening. However, if the decay is due to the friction material being worn away, adjustment only offers temporary improvement and cannot restore original performance.

Q5: Why do light-load devices still experience insufficient torque?

A: This is often because dynamic loads are underestimated. For example, vibration during movement, spring force from cables, and shock forces from user operation are often much higher than the static gravity torque calculated.

Conclusion | Summary

Torque decay is not an inexplicable mystery, but an inevitable result of the combined action of materials science, tribology, and mechanical structure.

For equipment manufacturers and design engineers, seeking an “everlasting” hinge is unrealistic. The correct engineering strategy should be:

- Deeply understand the operating conditions: Accurately assess dynamic loads and environmental factors.

- Reserve safety factors: Incorporate decay expectations into selection calculations.

- Strict verification testing: Conduct full life-cycle physical verification based on relevant industrial standards (ASTM, SEFA, EN).

Through scientific selection and reasonable expectation management, engineers can control torque decay within a safe range that does not compromise the user experience.