Blog

Stainless Steel Hinge Corrosion: 5 Technical Causes and Engineering Analysis

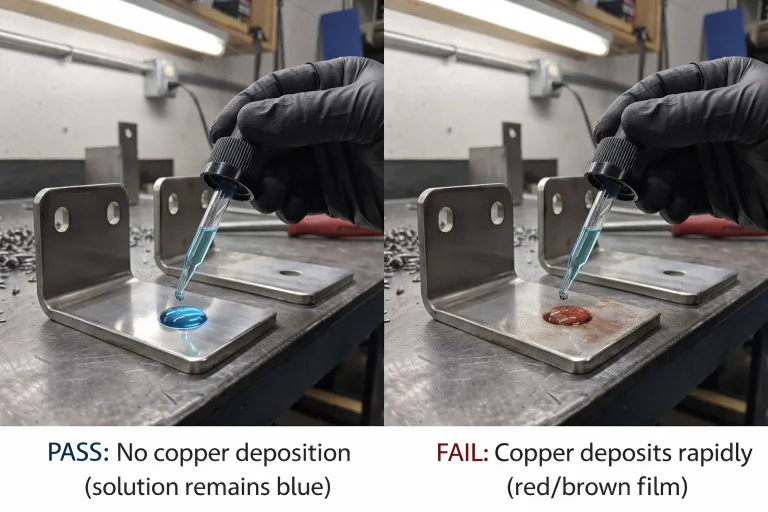

Functional Limits of Stainless Steel Passive Films Stainless steel is not a material that is absolutely immune to oxidation. Its corrosion resistance depends on a micro-thin passive film formed on the surface.…

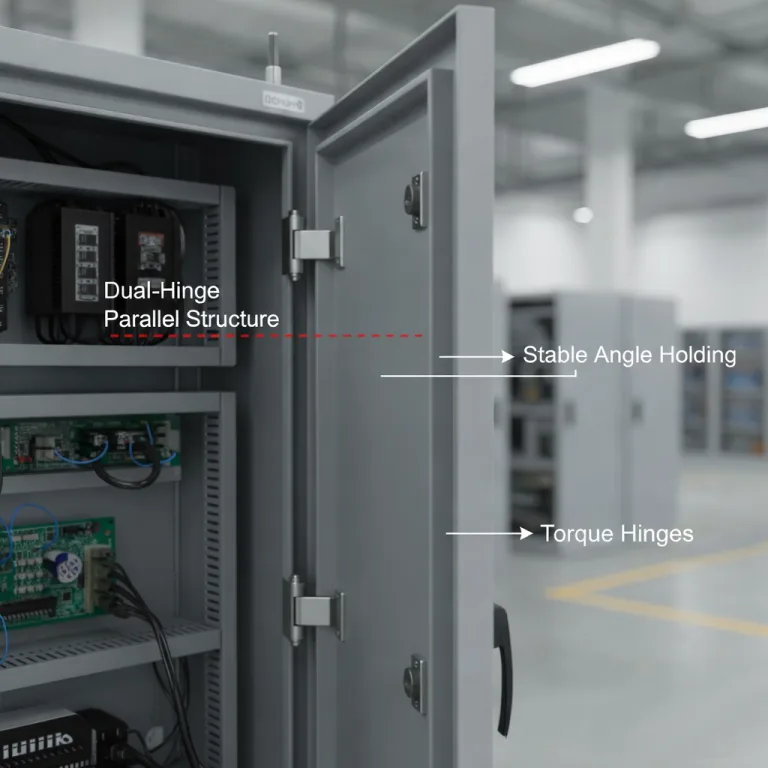

Why Do Torque Hinges Require Matched Pairs? (Technical Guide)

Why Do Torque Hinges Often Require Matched Pairs? Torque hinges are widely used in monitor stands, equipment covers, cabinet doors, hatches, and medical device panels. Across these products, engineering teams typically prioritize…

Industrial Hinge Cycle-Life Testing: Reliability & ROI Guide

In the design of industrial equipment, rail transit, and medical devices, the hinge is often mistaken for a simple connection component. However, real-world data indicates that hinge failure is one of the…

The Ultimate Guide to Industrial Enclosure Hinges: Selection, Materials, and Applications

In the fields of industrial manufacturing and electrical engineering, industrial enclosure hinges are more than just simple connection points. In fact, it is a core component that maintains the integrity of an…

Carbon Steel vs. Stainless Steel Hinges: A Guide to Material Selection & TCO

Engineering Overview Hinges may be small, but they have an outsized impact on enclosure uptime and user experience—smooth operation, long-term durability, and maintenance frequency, especially in outdoor, humid, or salt-spray environments. This…

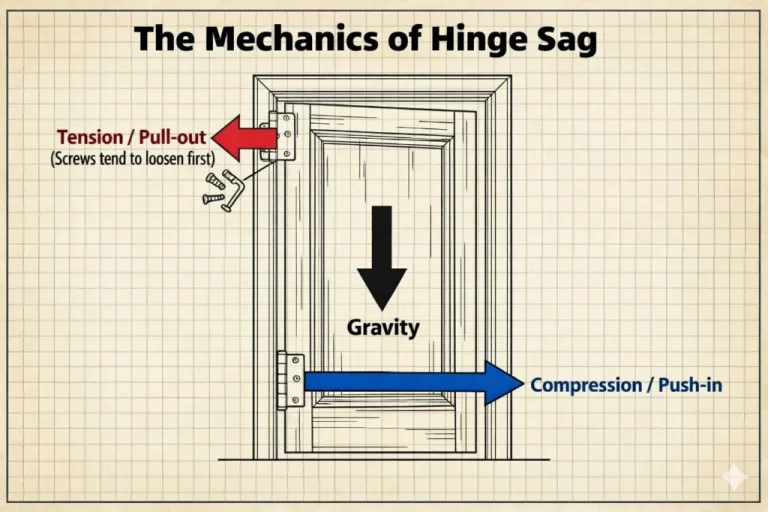

What Is Hinge Sag? Diagnosis, Repair, and Prevention Guide (ANSI Standards)

Quick Summary (Key Takeaways) What Exactly Is Hinge Sag? Definition and Mechanics (Simplified) Hinges perform two primary functions: bearing weight and rotating around an axis. The weight of the door is transferred…

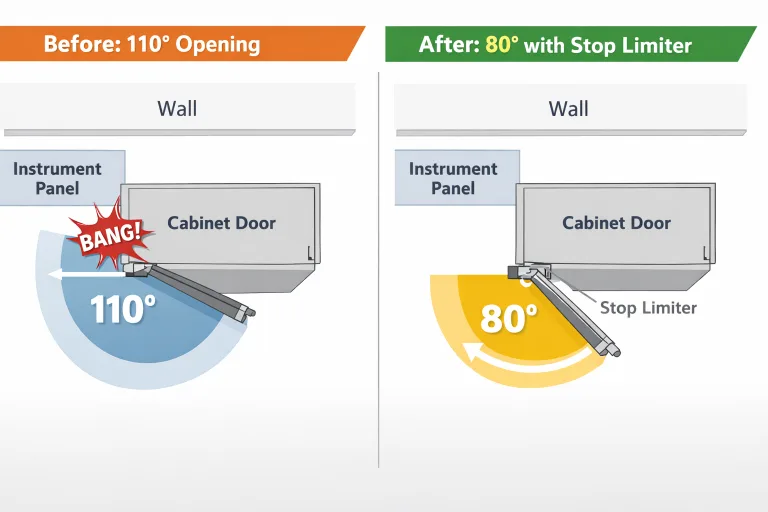

Industrial Stop Hinges (Integrated Stops): A Safety & Selection Guide for Equipment

Introduction: The Background of Limit Requirements in Industrial Scenarios In industrial equipment and vehicle applications, moving doors, lids, or hatches present serious safety hazards when they lack stop functionality—this is exactly what…

Hinge Alignment: The Hidden Cost of Industrial Cabinet Failure & How to Prevent It

In the design and manufacturing of industrial cabinets, heavy-duty machinery doors, and specialty vehicles, a frequently overlooked detail often leads to expensive consequences: Hinge Alignment. Field engineers frequently encounter the following typical…

Weld-On Industrial Hinges: The OEM Guide to High-Load Specifications

Bolts loosen; welds endure. In high-vibration and high-security industrial environments, Weld-On Industrial Hinges are the only viable engineering solution. This guide breaks down load dynamics, metallurgical compatibility, and the critical specs for…

Industrial Removable Pin Hinges: Procurement Guide & Benefits (ANSI/ASTM)

In the world of industrial hardware, Removable Pin Hinges (also known as loose pin, slip joint, or take-apart hinges) are a staple configuration for heavy-duty equipment doors, control cabinets, and inspection panels.…

Preventing Door Failure: Heavy-Duty Riveted Hinges for High-Vibration Environments

The reliability of industrial cabinets often fails in the details. Many engineering teams focus heavily on structural strength, IP ratings (sealing), and corrosion resistance grades. However, hinges are frequently treated as mere…

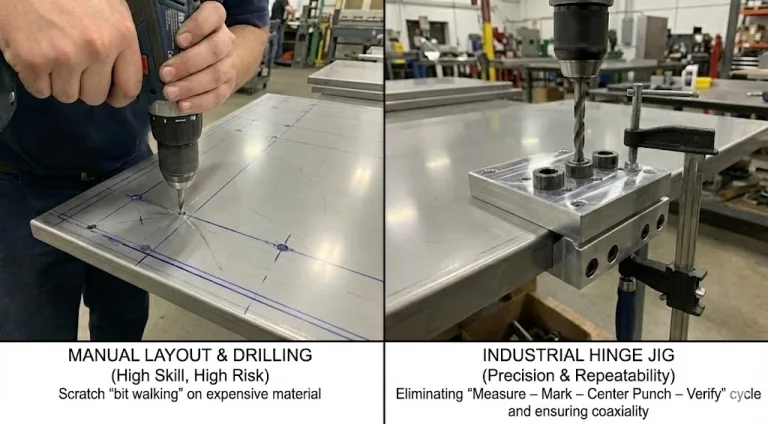

Industrial Hinge Installation: When Do You Need Hinge Jigs?

IP ratings are more than just cosmetic issues; they are production bottlenecks that kill profitability. For engineers and managers, the challenge isn’t just installing a hinge—it’s achieving repeatability at scale without relying…