Weld-On Industrial Hinges: The OEM Guide to High-Load Specifications

Bolts loosen; welds endure. In high-vibration and high-security industrial environments, Weld-On Industrial Hinges are the only viable engineering solution. This guide breaks down load dynamics, metallurgical compatibility, and the critical specs for “install-and-forget” reliability.

What is a Weld-On Industrial Hinge?

Defining the engineering scope is critical before drafting procurement specifications. Understanding the specific mechanics of weld-on hardware directly influences load calculations and cycle-life expectations.

Definition and Basic Structure

A Weld-On Hinge—frequently cataloged as a Bullet Hinge, Barrel Hinge, or Weld-on Pivot—is a heavy-duty connector engineered without pre-drilled mounting holes. The core design intent is fusion welding: bonding the hinge material directly to the metal substrates of the door frame and leaf.

This mounting method eliminates the structural weaknesses associated with fasteners. By removing the need to drill into load-bearing plates, it preserves the cross-sectional integrity of the metal and creates a permanent, high-strength bond superior to mechanical rivets or screws.

Common Structural Types

Adhering to BHMA (Builders Hardware Manufacturers Association) classifications, the primary weld-on configurations include:

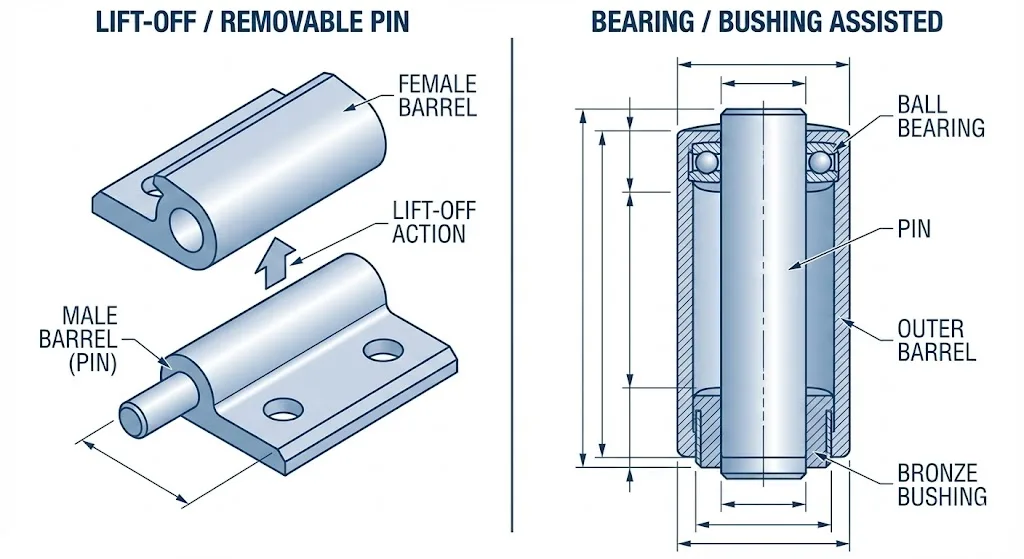

- Lift-Off / Removable Pin (Flag Hinges):

- Configuration: Features a male barrel (with pin) and female barrel (with bore) that detach easily.

- Operational Advantage: Facilitates rapid door removal without grinding off welds. This is a mandatory specification for equipment enclosures and HVAC access panels requiring routine maintenance in confined spaces.

- Greaseable (Integrated Zerk Fitting):

- Configuration: The barrel assembly includes a pressure-fit grease nipple.

- Corrosion Defense: Ideal for ISO 12944 C4/C5 environments. Regular lubrication acts as a “purge mechanism,” forcing out contaminated grease (which can turn into abrasive paste) and replenishing the protective film, thus preventing seizing.

- Bearing / Bushing Assisted:

- Configuration: Incorporates brass/bronze bushings or hardened steel thrust ball bearings between the barrel sections.

- Load Management: Essential for reducing the coefficient of friction. This allows heavy gates (>500kg) to meet ADA opening force requirements. Premium bearing models are rated for high-cycle applications, exceeding EN 1935 Grade 14 standards (200,000+ cycles).

Material and Metallurgical Compatibility

Selecting the correct alloy is paramount for weldability and environmental endurance.

- Carbon Steel (Mild Steel):

- Grades: Typically AISI 1035 or 1045.

- Pros: Excellent fusion properties, high tensile strength, cost-effective.

- Protection: Welding compromises the surface. Immediate application of zinc-rich primer or powder coating is required to protect the Heat Affected Zone (HAZ) from flash rust.

- Stainless Steel:

- Grades: AISI 304 (Standard) or AISI 316 (Marine Grade).

- Pros: Superior resistance to pitting and crevice corrosion. Grade 316 is the industry standard for offshore, coastal, or chemical processing facilities.

- Welding Protocol: Requires specific filler rods (e.g., ER316L) to maintain the austenitic structure and prevent intergranular corrosion.

- Aluminum:

- Application: Lightweight transport (trailers, aerospace). Requires TIG welding proficiency and compatible 6000-series alloys.

Why Does Industry Prefer Weld-On Designs? (Core Engineering Benefits)

Industrial applications demand durability far exceeding residential hardware. For engineers and procurement officers, the shift to weld-on solutions is justified by six critical performance metrics.

Superior Structural Strength and Load Distribution

Bolted hardware relies entirely on the Shear Strength of the fastener and the hole wall. Under dynamic loading, bolt holes often suffer from elongation (ovality), causing alignment failure.

- The Fusion Advantage: Welding creates a monolithic structure, distributing mechanical stress evenly across the entire weld length rather than concentrating it at drill points.

- Performance Data: Weld-on hinges typically exhibit an Ultimate Load Capacity 30-50% higher than bolted equivalents of similar physical dimensions. Heavy-duty variants can support radial loads exceeding 3,000 lbs (1.36 tons) per pair.

- Compliance: A properly executed full-penetration weld meets AWS D1.1 structural codes, often yielding a bond stronger than the base metal itself.

Immunity to Vibration and Loosening

Machinery, gensets, and heavy transport vehicles are subject to constant harmonic vibration.

- Threaded Failure: The Junker Vibration Test proves that threaded fasteners naturally lose preload under transverse vibration, leading to self-loosening or fatigue fracture.

- The Welded Solution: A fused joint is rigid and static. For mining equipment or vibrating screens, welding is the only method to guarantee a “zero-maintenance” connection that will not back out over time.

High-Security and Tamper Resistance

Facilities like penitentiaries, armories, and data centers prioritize physical denial of access.

- Vulnerability: Exposed hex heads or Phillips screws are weak points exploitable by simple hand tools.

- Hardening: Weld-on bullet hinges present a smooth, cylindrical profile with no accessible grip points. Removal requires destructive cutting tools (torches or angle grinders), satisfying the delay-time requirements of high-security protocols.

Adaptability to Irregular Profiles

Industrial frames often utilize structural steel shapes (I-beams, C-channels) or tubular posts with varying wall thicknesses.

- Retrofit Issues: Drilling and tapping thick structural steel (>10mm) is labor-intensive. Furthermore, standard ANSI hole patterns rarely align with custom fabrications.

- Mounting Flexibility: Welding is agnostic to hole patterns. Fillet welds easily secure hinges to round tubes, convex surfaces, or edge profiles, making them the standard for chain-link fence gates and non-standard bollards.

Sanitary Sealing and Contamination Control

In food processing (F&B) and pharmaceutical sectors, crevices harbor pathogens.

- Hygienic Design: Bolted flanges create microscopic gaps where liquids accumulate, leading to bacterial growth and rust.

- Hermetic Seal: A continuous weld bead eliminates the interface gap between the hinge and frame. Combined with sealed bearings, this setup aligns with NSF/ANSI sanitary design principles for wash-down environments.

Optimized Total Cost of Ownership (TCO)

While initial fabrication requires skilled labor, the lifecycle economics favor welding.

- OPEX Reduction: Eliminates the labor costs associated with re-torquing bolts or replacing corroded washers.

- Uptime: Prevents catastrophic door detachment due to fastener shear. For automated lines and logistics fleets, this “install-and-forget” reliability maximizes operational availability.

Vertical Application Analysis: Where is Welding Mandatory?

Specific industrial sectors mandate weld-on specifications due to extreme operating conditions.

Heavy-Duty Steel Doors & Portals

- Context: Blast-resistant doors, aircraft hangars, radiation shielding gates.

- Load Profile: Leaves exceeding 500kg generate massive bending moments at the pivot point.

- Solution: High-capacity Carbon Steel Bullet Hinges.

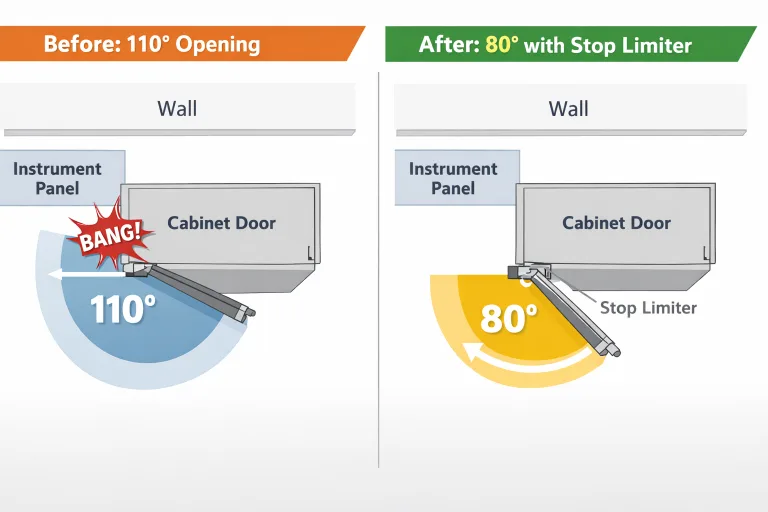

- Best Practice: Utilize a multi-point configuration (one hinge every 0.75m) to linearize the load and prevent plate tearing.

Perimeter Security & Cantilever Gates

- Context: Substation enclosures, correctional facilities, automated driveway gates.

- Stressors: High wind loads, cantilever forces, and potential vehicular impact.

- Solution: Weld-on hinges adaptable to round fence posts.

- Upgrade: Employ Adjustable Weld-On Modules (e.g., Locinox style) to compensate for post-installation concrete settling or gate sagging.

Waste Management & Intermodal Containers

- Context: Roll-off dumpsters, scrap metal skips, shipping containers.

- Environment: High-impact dumping cycles and exposure to acidic leachate.

- Standard: Must comply with ISO 1496 structural racking tests.

- Solution: Fully welded connections are non-negotiable. Screws fail rapidly under the torque of compactors. Sealed pin designs are required to prevent chemical ingress.

Commercial Transport (Truck & Trailer)

- Context: Lowboy trailers, dump truck tailgates, utility bodies.

- Dynamics: Constant road shock and high G-force vibration.

- Compliance: DOT regulations penalize detached road debris heavily.

- Solution: Welding offers safety redundancy. A cracked weld propagates slowly (allowing detection), whereas a sheared bolt causes immediate catastrophic failure.

Mining & Agricultural Machinery (OEM)

- Context: Excavator cabs, tractor cowlings, rock crusher access.

- Hazards: Mud, silica dust, and high-pressure washing.

- Solution: Heavy-duty hinges with Grease Zerks.

- Mechanism: Prevents the “lapping compound effect” (grease + dust = sandpaper) by allowing operators to flush contaminants from the pivot daily.

Weld-On vs. Bolt-On: Technical Comparison Matrix

A side-by-side engineering evaluation for sourcing decisions.

| Feature | Weld-On Hinge | Bolt-On Hinge | Ideal Application |

| Structural Integrity | Superior. Monolithic bond; high shock absorption. | Moderate. Limited by shear strength of fastener/hole. | Armored doors, Heavy gates (>200kg). |

| Install Precision | High Skill. Permanent fixture; requires jigging/clamping. | Low Skill. CNC pre-drilled or slotted for adjustment. | DIY, Residential, Lightweight retrofit. |

| Vibration Proofing | Absolute. No mechanical threads to loosen. | Low. Requires Nyloc nuts or thread-lockers. | Gensets, Trailers, Machinery. |

| Tamper Resistance | Maximum. Smooth barrel, no drive heads. | Minimum. Vulnerable unless security screws used. | Prisons, Server Cages, Hazmat. |

| Substrate Versatility | Limited. Metals must be weld-compatible. | High. Wood, fiberglass, composites, concrete. | Mixed-material assemblies. |

| Aesthetics | Streamlined. Minimalist barrel profile. | Industrial. Visible flanges and hardware. | Architectural metalwork. |

| Maintenance Cycle | Minimal. Lubrication only. | Periodic. Torque checks required. | Remote/Inaccessible sites. |

Selection Guide: Specifying the Correct Weld-On Hinge

Avoid procurement errors by verifying these six technical parameters.

Load Calculation & Sizing

Static weight is only one variable.

- Formula: Design Load = (Door Mass + Hardware) × Safety Factor (SF).

- Industrial Standard: Use SF 1.5 to 2.0.

- Spacing Rule: “One hinge per 30 inches (750mm) of vertical height.”

- Vector Analysis: Determine if the primary force is Radial (downward gravity) or Axial/Thrust (side load). Wide doors exert exponential leverage on the top hinge.

Metallurgical Compatibility

- Rule: Match hinge material to the frame (Carbon to Carbon, Stainless to Stainless).

- Galvanic Warning: Welding Carbon Steel to Stainless Steel requires specialized transition fillers (e.g., 309L) to avoid brittle welds and accelerated galvanic corrosion. Aluminum to Steel welding is metallurgically impossible without bimetallic transition inserts.

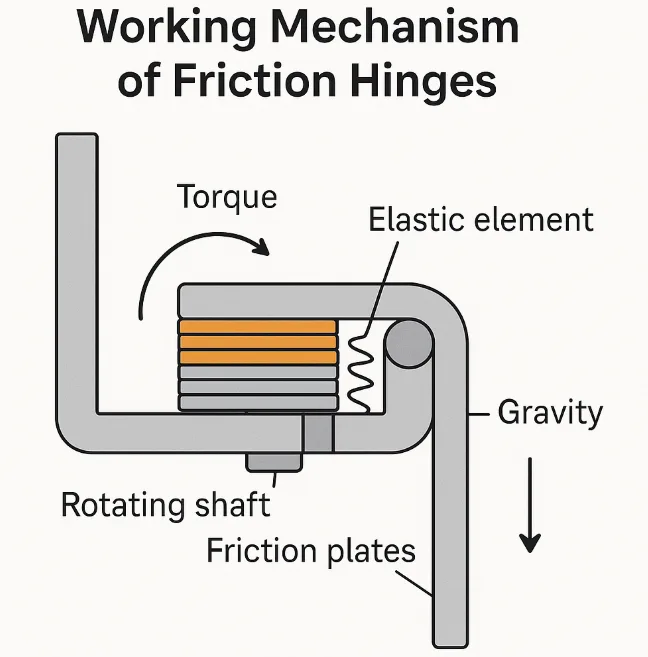

Bearing Technology

- Low Duty: Steel-on-Steel (Standard).

- High Cycle: If usage exceeds 400 cycles/day, specify Oil-Impregnated Bronze Bushings or Needle Bearings.

- Heavy Load: For vertical loads >500kg, Thrust Ball Bearings are mandatory to prevent friction welding and reducing opening torque.

Pin Architecture

- Fixed Pin: Non-removable for maximum security.

- Loose/Lift-Off Pin: Allows door removal. Install Note: Mount opposed lift-off hinges (one up, one down) to lock the door vertically while allowing removal only when intended.

- Greaseable Pin: Mandatory for outdoor/abrasive zones.

Surface Condition

- Supply State: Typically Self-color / Mill Finish.

- Prep: Hinge barrels are often shipped with a rust-preventative oil film. This must be degreased prior to welding to prevent porosity and hydrogen embrittlement in the weld bead.

Certification Requirements

- Validate compliance with NFPA 80 (Fire Doors) or EN 1935 (Single Axis Hinges) based on regional safety codes.

Manufacturing Protocol: Installation & Failure Prevention

Top-tier hardware fails if the welding process is flawed.

Collinear Alignment (The Critical Axis)

- The Challenge: Hinge axes must be concentric.

- Failure Mode: A misalignment of just 1° creates “hinge binding,” generating internal forces that will eventually fatigue the metal or shear the pin.

- Process: Use laser alignment tools or straight edges. Tack weld first, then test the swing arc. Use shims to correct minor planar deviations before laying the final bead.

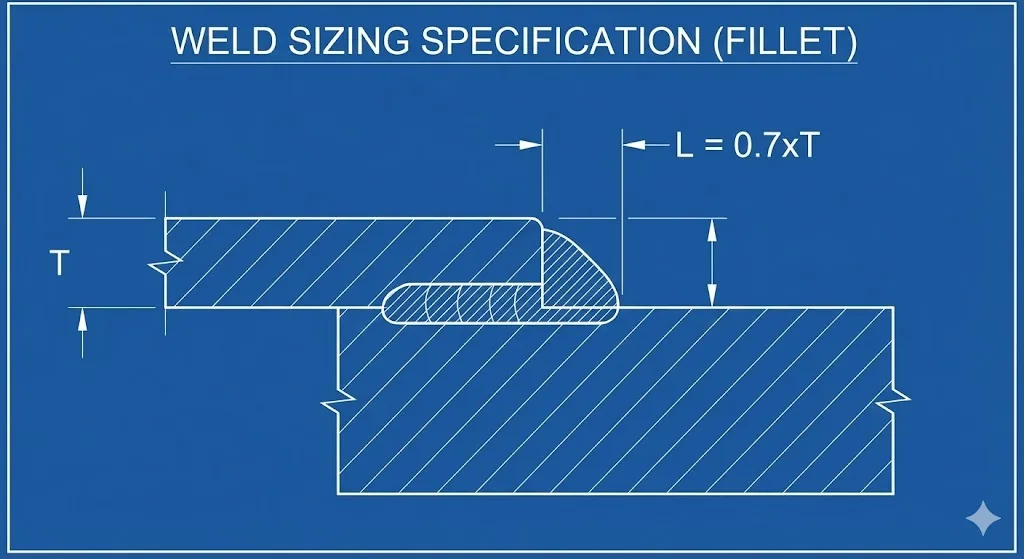

Weld Sizing and Penetration

- Avoid: Relying on simple tack welds for service.

- AWS Recommendation: Effective weld length should cover at least 80% of the barrel length.

- Fillet Size: The fillet weld leg size should equate to ~0.7x the hinge plate thickness to maximize shear resistance.

Thermal Management & Distortion

- Risk: Welding heat travels rapidly through the barrel.

- Damage: Excessive heat can melt internal nylon washers, liquify grease, or anneal hardened bearings.

- Mitigation:

- Heat Sink: Wrap the barrel in a wet rag.

- Disassembly: If using lift-off models, weld separate halves and reassemble post-cooling.

- Technique: Use Stitch Welding (intermittent welds) to limit thermal input.

Post-Weld Passivation

- Restoration: High heat creates an oxidation scale prone to rust.

- Finish: Mechanically grind slag. Immediately apply cold galvanizing compound or epoxy primer. For 316 Stainless, utilize pickling paste to restore the passive chromium oxide layer.

FAQ (Technical & Sourcing)

Q1: Is the load rating of a weld-on hinge definitively higher than bolt-on?

A: Yes. By utilizing the entire contact length for fusion, weld-on hinges eliminate the stress risers found in drilled holes. A qualified weld offers structural continuity equivalent to the base metal.

Q2: Is replacement feasible for MRO (Maintenance, Repair, Operations)?

A: Feasible but labor-intensive. It requires scarfing (gouging) the old weld and grinding the surface flush. We recommend oversizing the hinge (SF 2.0+) during the design phase to achieve a “life-of-asset” installation.

Q3: What constitutes the best specification for marine environments?

A: AISI 316 (EN 1.4401) Stainless Steel. Post-weld passivation is critical; otherwise, the weld bead will corrode faster than the hinge body.

Q4: How do we control thermal distortion on thin doors?

A: Employ Stitch Welding (skip welding) rather than a continuous run. Weld from the center outwards. Clamping the door with a slight “pre-camber” can counteract cooling shrinkage.

Q5: When are bearing-assisted models required?

A: Specify bearings if the door exceeds 150kg or operates >10 times daily. Bearings convert sliding friction to rolling friction, reducing wear and operator effort.

Conclusion: The Engineering Case for Weld-On Hinges

The dominance of weld-on designs in industrial sectors is a calculated engineering decision, not merely a tradition.

- Structural Integrity: Welding ensures the hardware becomes an integral part of the chassis, capable of withstanding heavy static loads and dynamic impact.

- Operational Reliability: It is the only fastening method that remains impervious to the loosening effects of vibration.

- Asset Protection: Offers superior security profiles for sensitive infrastructure.

Guidance for Procurement Teams:

Move beyond unit-price comparisons. Evaluate the Total Door Mass, Cyclic Frequency, and Corrosivity Category. Investing in high-grade, bearing-equipped weld-on hinges minimizes TCO by eliminating the downtime associated with fastener failure.